STEEL PIPES

INTRODUCTION

API PIPE : API 5L Seamless Line Pipe

Standard Specification for Line Pipe

The American Petroleum Institute specification API 5L covers seamless and welded steel line pipe. This steel pipe is used for pipeline transportation systems in the petroleum and natural gas

industries. API 5L is suitable for conveying gas, water, and oil. Size range is limited only by manufacturer’s capabilities.

Specifications for API 5L adhere to the International Organization for Standardization ISO 3183, which standardizes pipeline transportation systems within the materials, equipment and offshore structures for petroleum, petrochemical, and natural gas industries. The technical committee authoring the standards recognized that there are two basic Product Specifications Levels (PSL) of technical requirements and therefore developed PSL 1 and PSL 2. PSL 1 is a standard quality for line pipe where PSL 2 contains additional chemical, mechanical properties, and testing requirements.

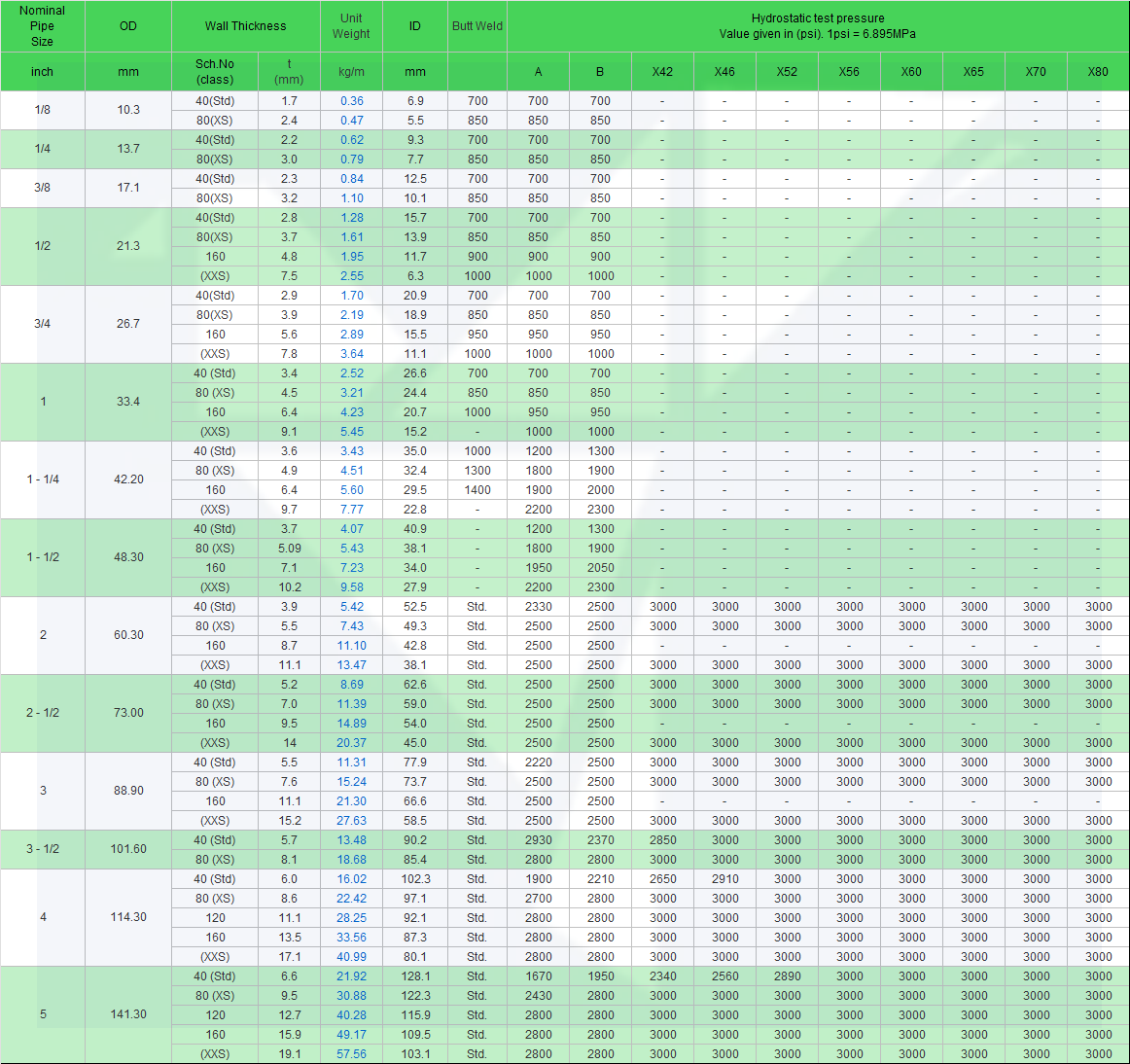

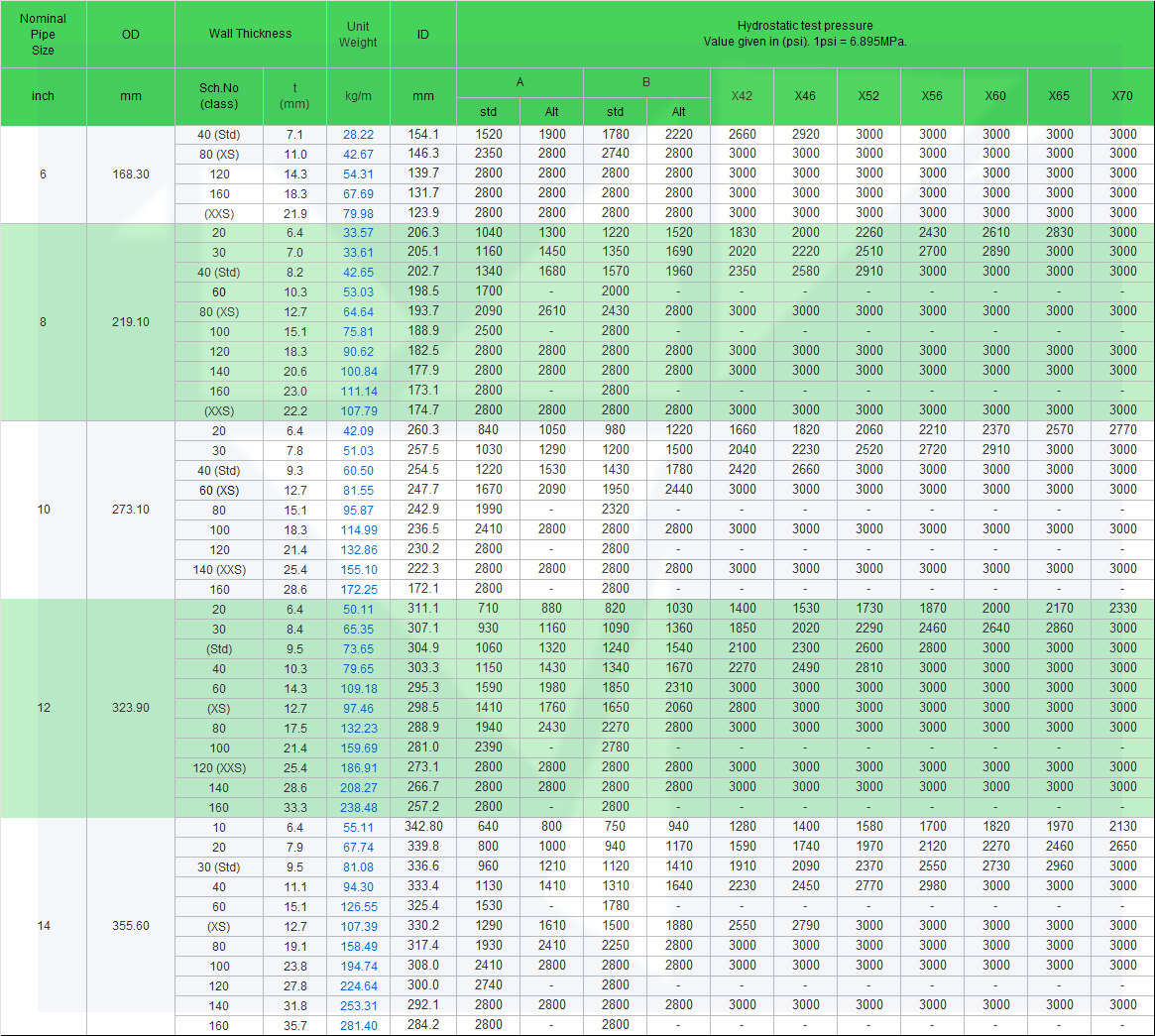

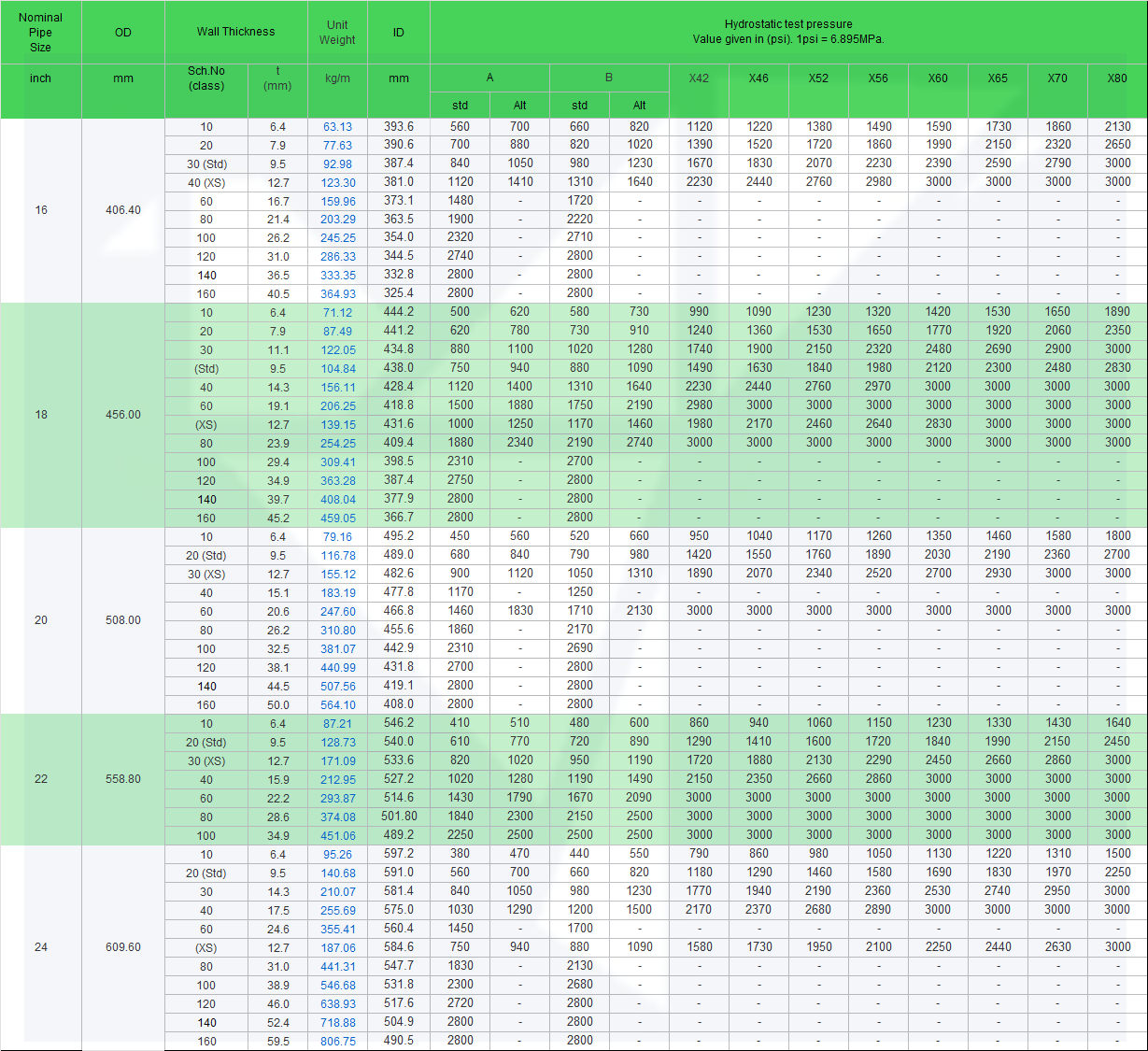

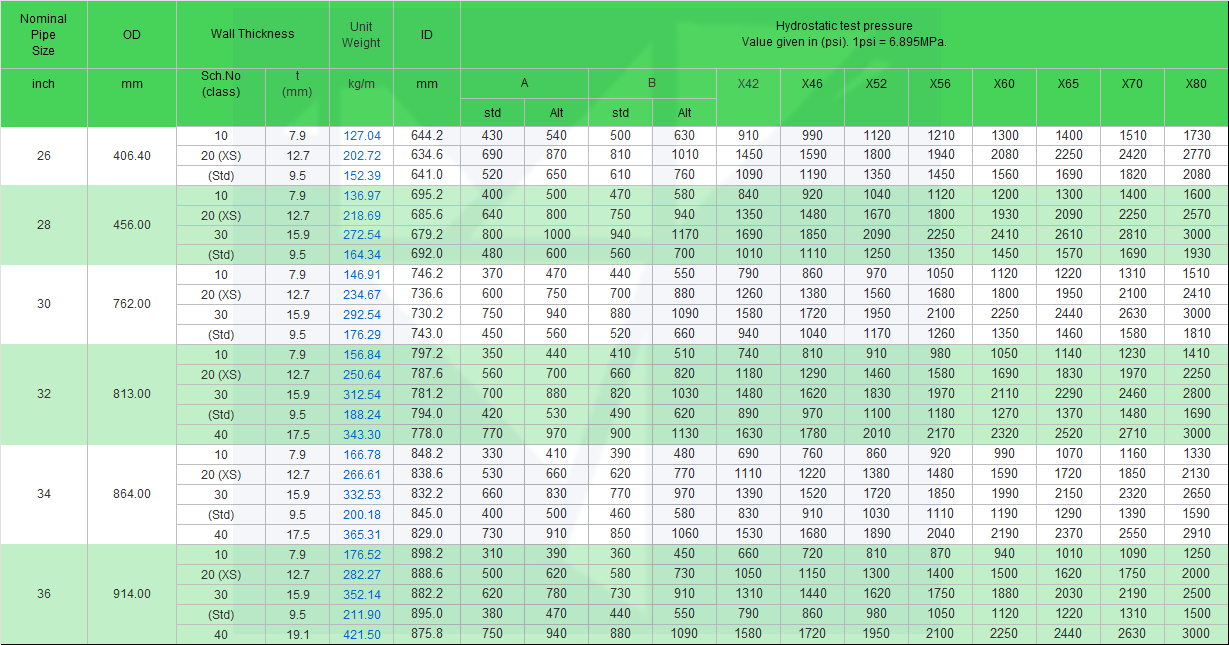

Grades covered by this specification are A25, A, B (and the following "X" Grades), X42, X46, X52, X56, X60, X65, X70, X80. The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

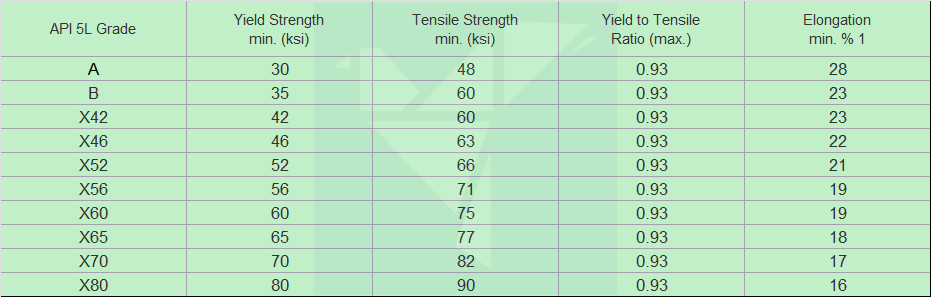

API 5L Line Pipe Physical Properties

Line pipe grade designations come from API Spec 5L Specification for Line Pipe. Standard Line

Pipe has grade designation A and B. Stronger grades have the designation X followed by the

specified minimum yield strength of the pipe steel, measured in kilopounds per square inch

(abbreviated ksi), e.g. X60 for pipe having a minimum yield strength of 60 ksi. See the table

below for the standard available grades.

Line Pipe Physical Properties

1. API 5L elongation figures vary with specimen dimensions. Values shown for 0.2 sq. in. specimen.

Line pipe mechanical testing usually omits Reduction of Area (RA) measurement reporting, and Charpy V-Notch (CVN) testing. This prevents use of this pipe as body material above 36 ksi yield strength for API Spec 6A equipment without retesting for Reduction of Area, and in the case of low temperature service, Charpy V-Notch testing as well.

CAUTION: Do not confuse pipe manufactured to meet ASTM A106 Grade A or B as interchangeable with API 5L Grade A or B without close observation of the mill test reports. The two pipe specifications overlap, but vary. Pipe may or may not meet both specs.

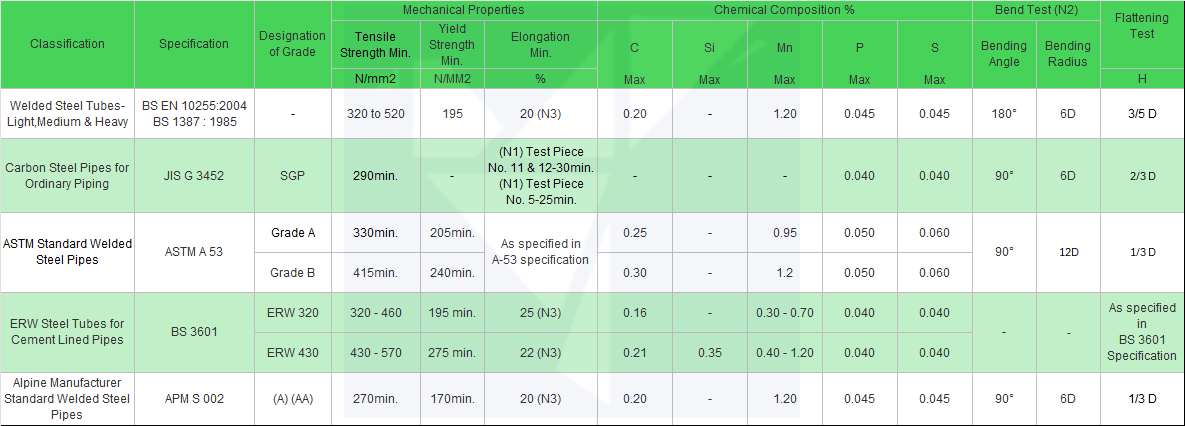

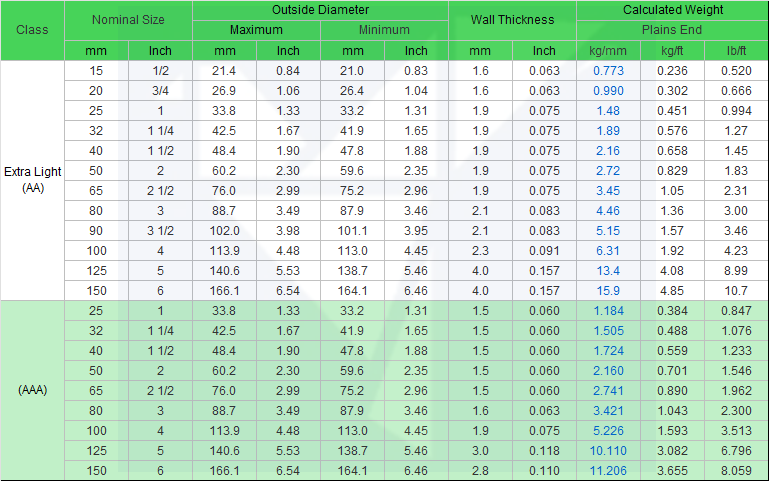

Standard Specification - PIPES

Notes:

(N1) - When the tesile test is carried out on No. 12 or No.15 test piece for the pipe under 8mm in wall thickness the minimum value of elongation shall be obtained by substracting 1.5% from the thickness values of elongation given in Table above for each 1mm decrease in wall thickness and rounding off to an integer in accordance with JIS Z 8401

(N1) - The values of elongation given in table above shall not applied to the pipe whose nominal size 32 mm or smaller.

(N2) - Bend test in table above only applied to pipes of nominal size 2" (50mm) or smaller.

(N3) - Gauge length Lo = 5.65 √So (%)

H - Distance between the plates

D - Outside diameter of the pipe

APM S 002 - Manufacturer standard

WELDED PIPES

FAQ

API stands for American Petroleum Institute specification and ERW stands for Electric Resistance Welded pipe. The API 5L covers seamless and welded steel line pipe. This steel pipe is used for pipeline transportation systems in the petroleum and natural gas industries. API 5L is suitable for conveying gas, water, and oil.

A welded pipe is fabricated by rolling steel coil until the gauge thickness, which will leave seam on the pipe's body. Seamless pipe are consider stronger without weld seam.