HOLLOW SECTIONS

INTRODUCTION

Structural Hollow sections are widely used in the construction industry for both efficiency and aesthetics. This means the quality and type of hollow section employed is vitally important for the overall performance of a structure.

When understanding the differences in the quality and performance between hot finished and cold formed hollow sections, there are four main considerations that have to be taken into account: (I) Manufacture, (II) Properties, (III) Certification and (IV) Cost.

(l) Manufacture

The manufacturing processes of hot finished and cold formed hollow sections are very different. Hot finished hollow sections are formed at normalizing temperature (Approx. 900°c) and are produced in accordance with standard EN 10210-1: 2006; while cold-formed hollow sections are formed at ambient temperatures and are produced in accordance with standard EN 10219-1:2006.

This results in several key differences, the main one being that hot finished hollow sections pass through a furnace and have a much tighter corner profile as a result of the metal flow during the forming process. Cold formed, on the other hand, exhibit a high degree of cold working in the corner regions during the forming process. This means that they could be susceptible to corner cracking if manufactured with tight radius corners.

(ll) Properties

When choosing between hot finished or cold formed hollow sections, particular issues must be considered to ensure the correct type is specified for a successful outcome.

(lll) Certification

A key topic in today’s construction industry is the certification of material used and if it is suitable for the specified job. Both the hot finished – EN 10210-1: 2006 and cold formed – EN 10219-1:2006 say the same in regard to testing and certification and are split into two categories - ‘specific test’ and a ‘non-specific test’. To ensure correct specification, the differences should be understood.

A non-specific test states that ‘tests shall be carried out by the manufacturer, in accordance with his own procedures. The results supplied need only be “representative” of the material grade and so are generally not from the products actually supplied and sometimes not even from material of the same dimensions. Non-specific testing is accompanied by a Test Report.

A specific test states that ‘tests shall be carried out on the actual products to be supplied, or on test units of which the product to be supplied is a part, or when applicable on all hollow sections‘. Specific testing is accompanied by a Test certificate.

(lV) Costing

We obviously need to consider material costs and at first it seems straightforward that cold formed sections are far cheaper than hot finished of a similar grade. However, we also have to compare the correct specification of cold formed, in this case EN 10219, which must be supplied with specific testing to be truly suitable for construction and not commodity cold formed material intended for general engineering applications that is supplied with only a test report. This provides a more realistic price comparison between hot finished and cold formed, in which cold formed still has a price advantage, but against this we have to account for the better sectional properties of hot finished and its greater strut curve capacities. From this it can be seen that it may not be as simple as originally thought to compare hot finished with cold formed on a size by size basis.

Key Points

- Ensure the correct specification is specified and used throughout.

- Cold formed should not be substituted for hot finished without first considering the design and fabrication implications.

- It is important to ensure that materials have the correct certification i.e. TEST CERTIFICATE NOT TEST REPORT.

- Cold formed sections that are correctly specified, correctly produced and supplied with appropriate certification are suitable for all forms of construction.

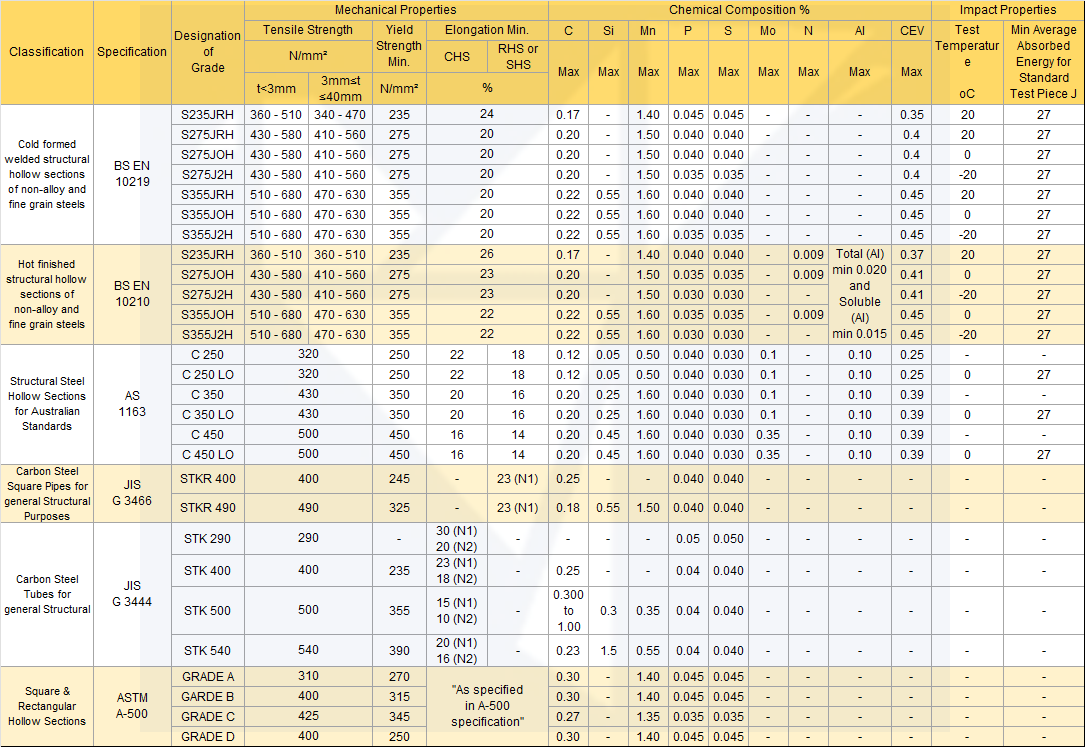

STANDARD TECHNICAL SPECIFICATION | HOLLOW SECTIONS

Notes:

- SS 104 specification can be produced upon request.

- The impact properties of steel qualities JR and JO are verified by laboratory testing only when specified at the time of the inquiry and order.

- The steel qualities JO and J2 can be produced upon request with extra cost.

- (N1) Test piece No. 11 and 12.

- (N2) Test piece No. 5.

- When the tensile test is carried out on No.5 and 12 test piece for the tube under 8mm in wall thickness, the minimum elongation value shall be determined by reducing 1.5% per 1mm of decrease in wall thickness from the values given in the table above and rounding off the value obtained to integer in accordance with JIS Z 8401. - t-thickness

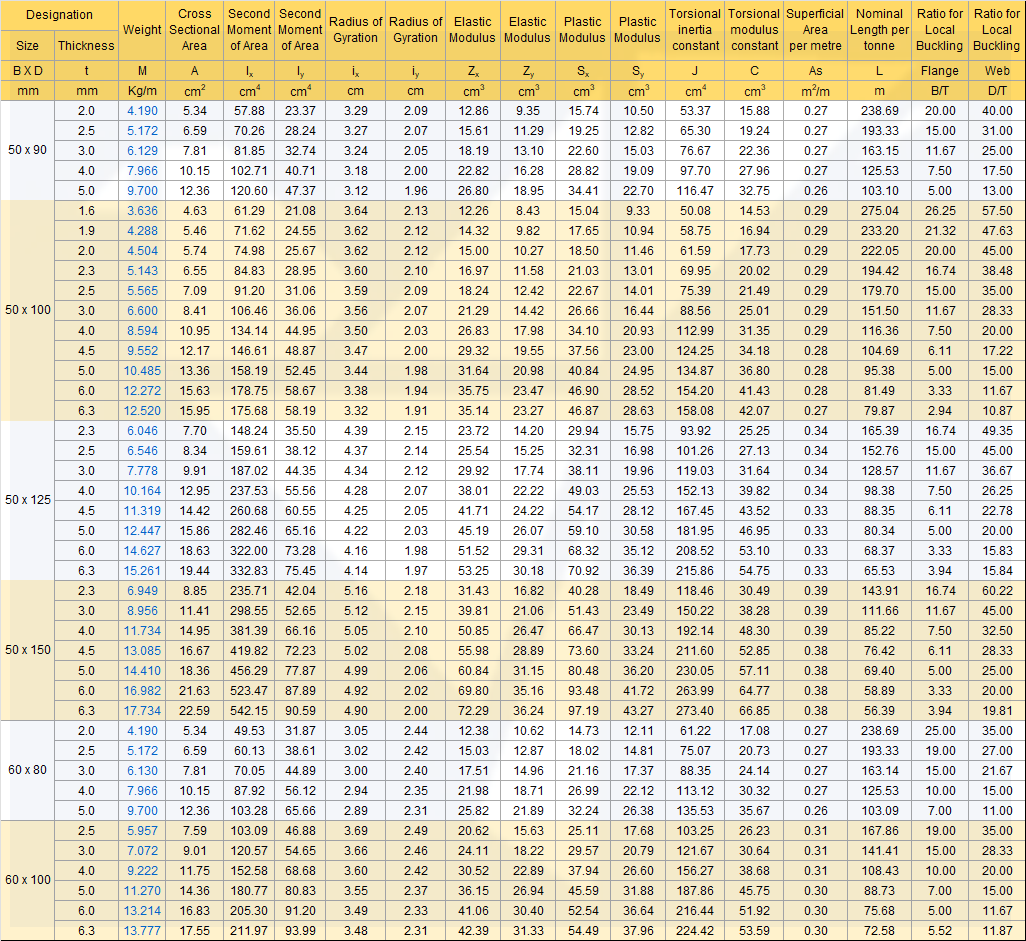

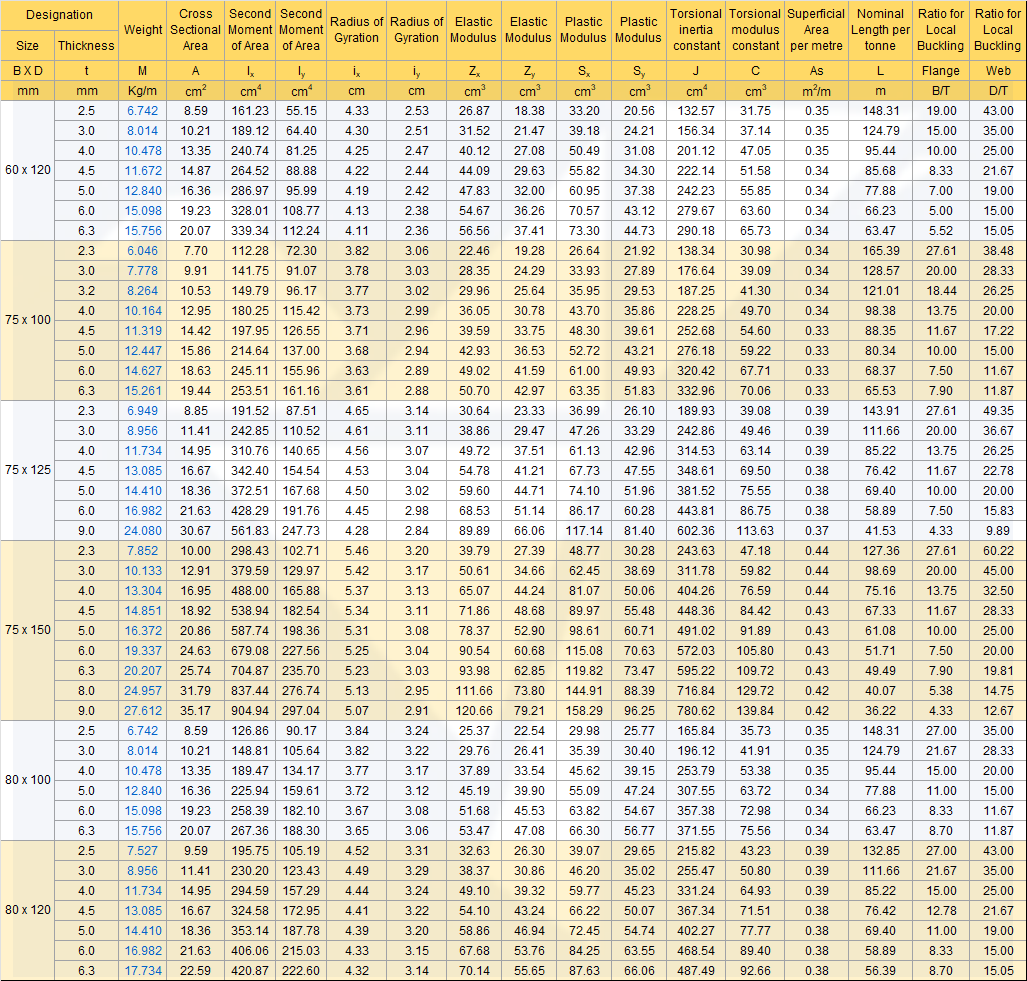

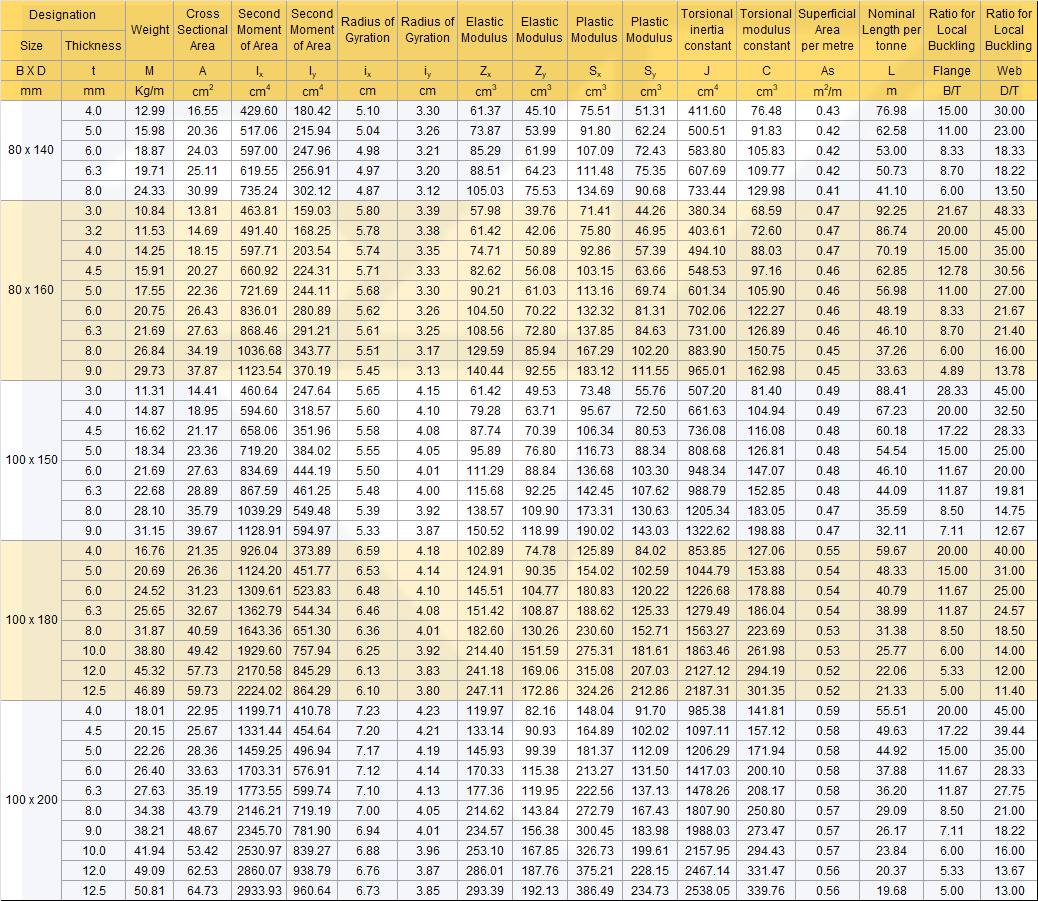

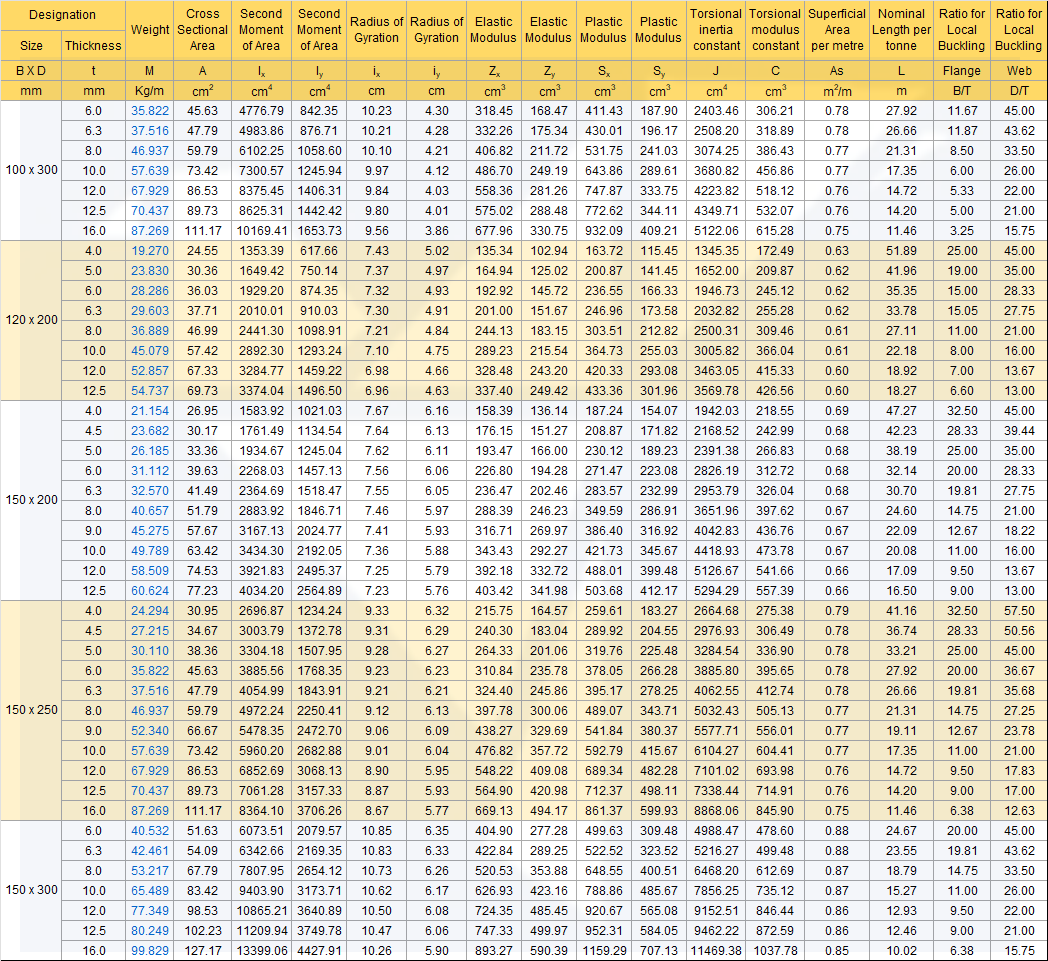

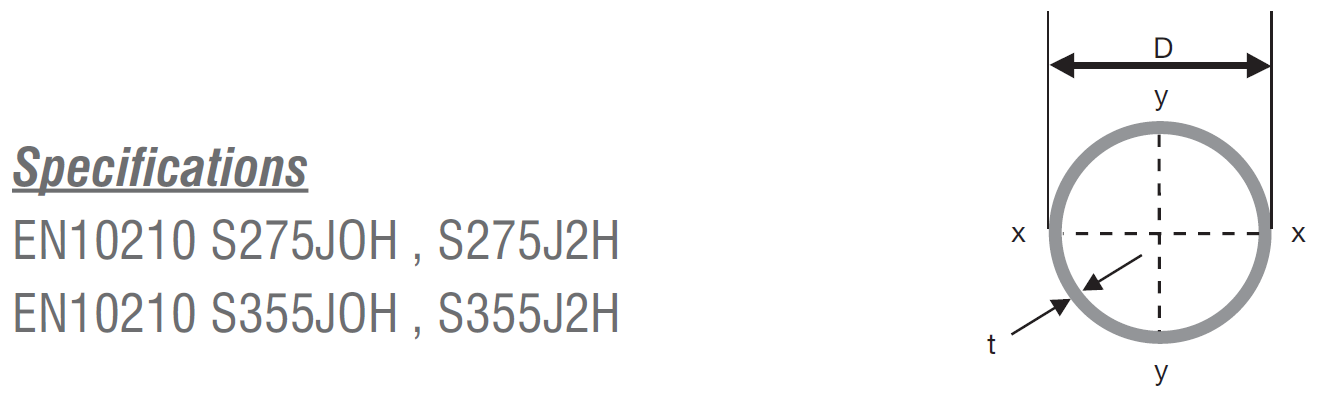

CHS - Circular Hollow Sections

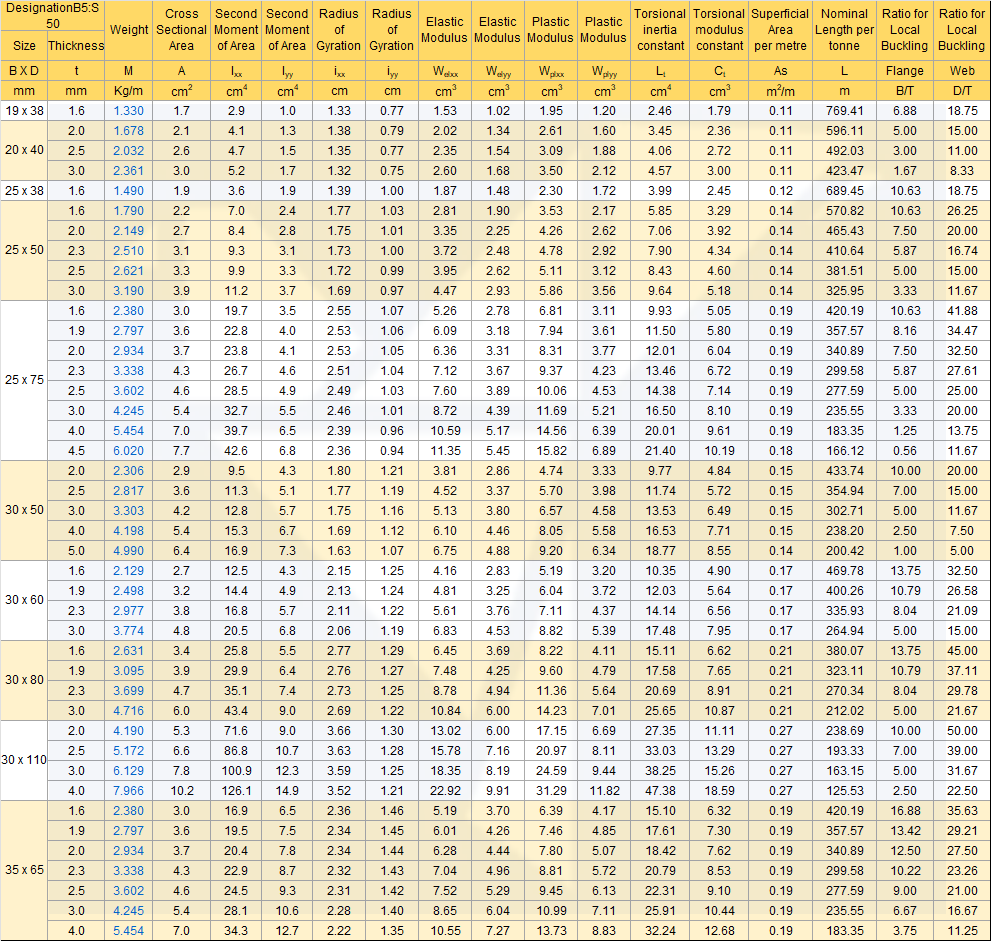

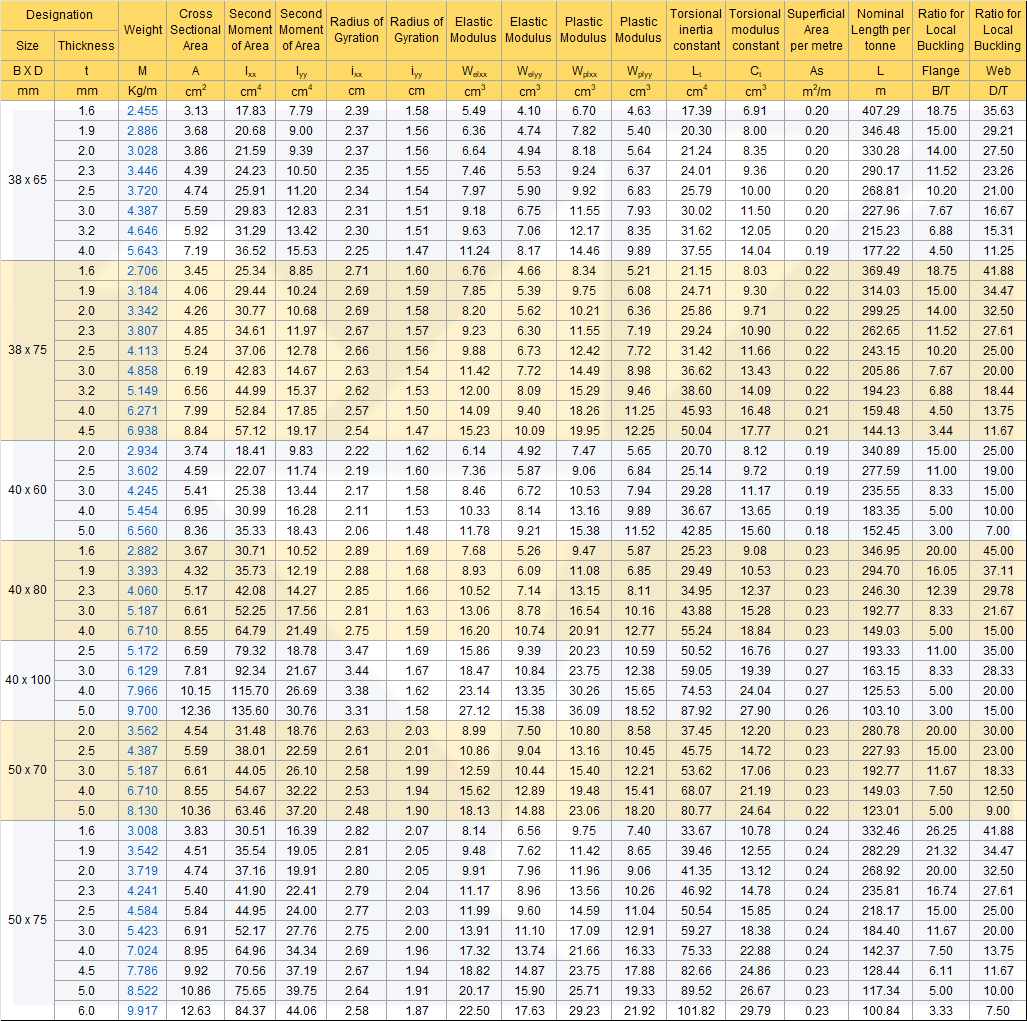

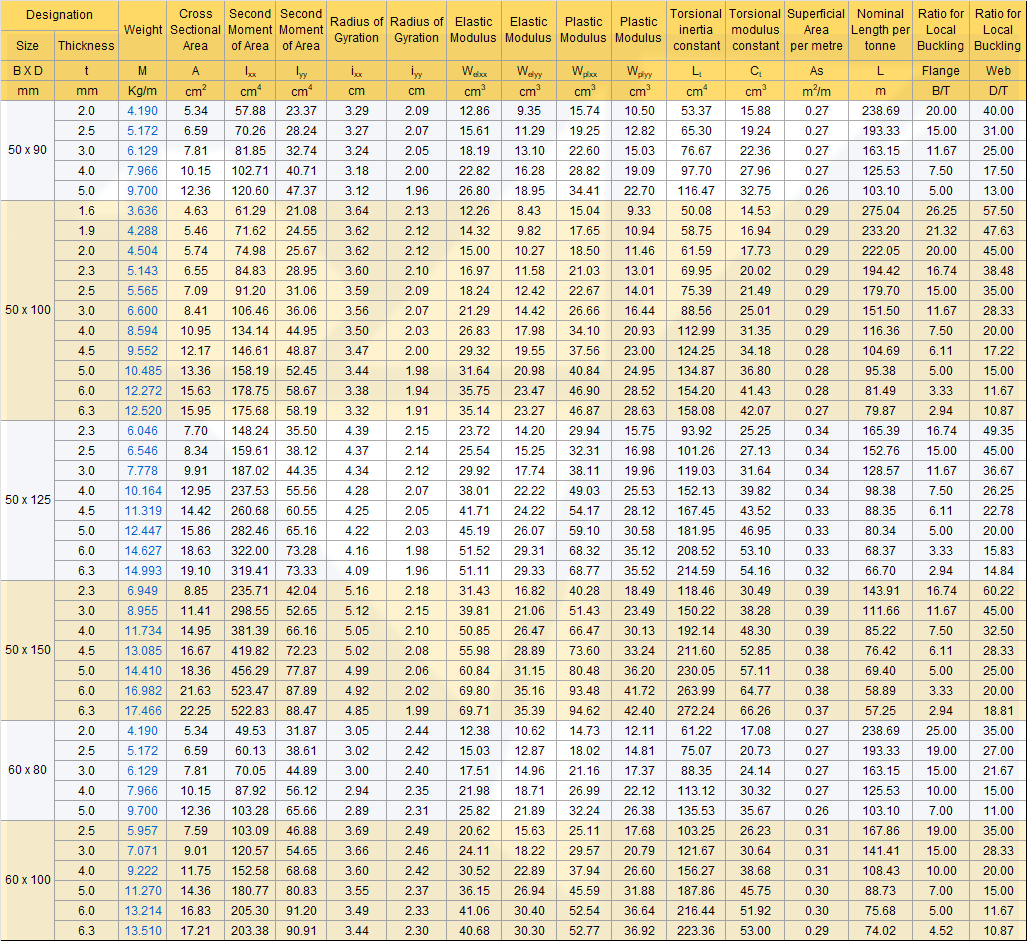

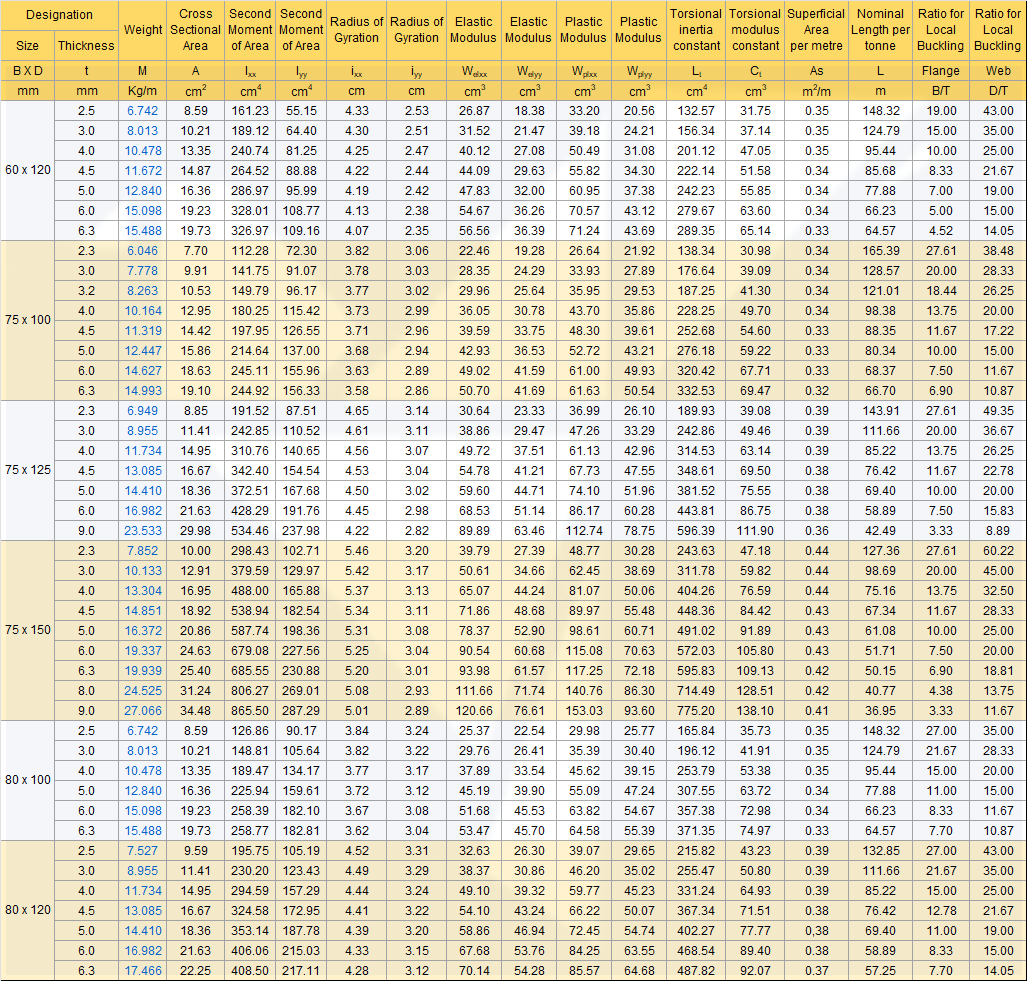

RHS - Rectangular Hollow sections

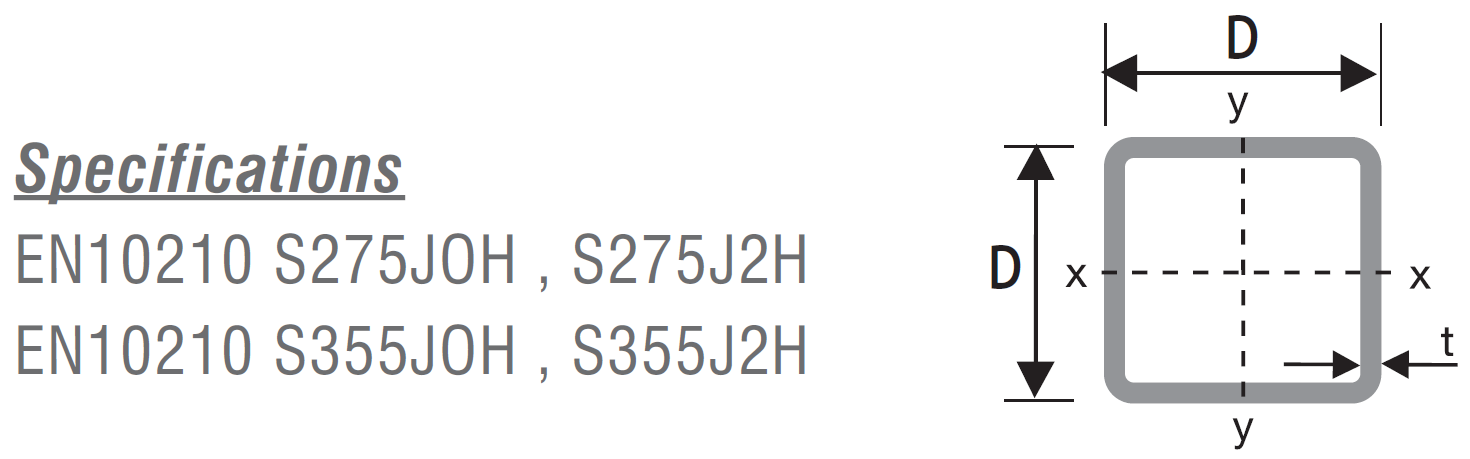

SHS - Square Hollow Sections - The BS EN 10210 specifies technical delivery conditions for hot finished hollow sections and applies to sections formed hot, with or without subsequent heat treatment, or formed cold with subsequent heat treatment to obtain equivalent metallurgical conditions to those obtained in the hot formed product

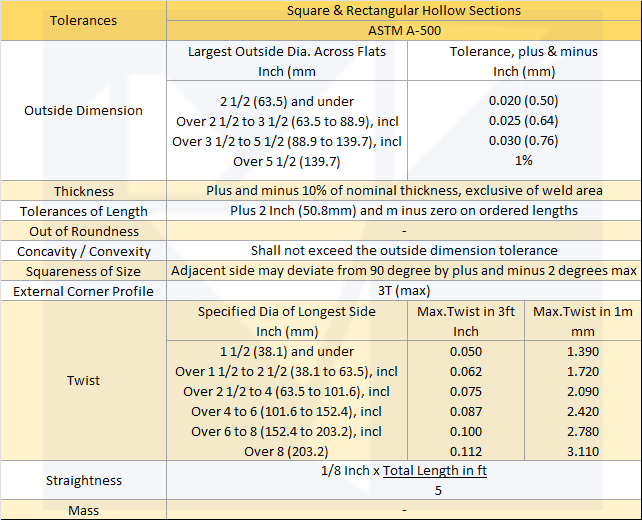

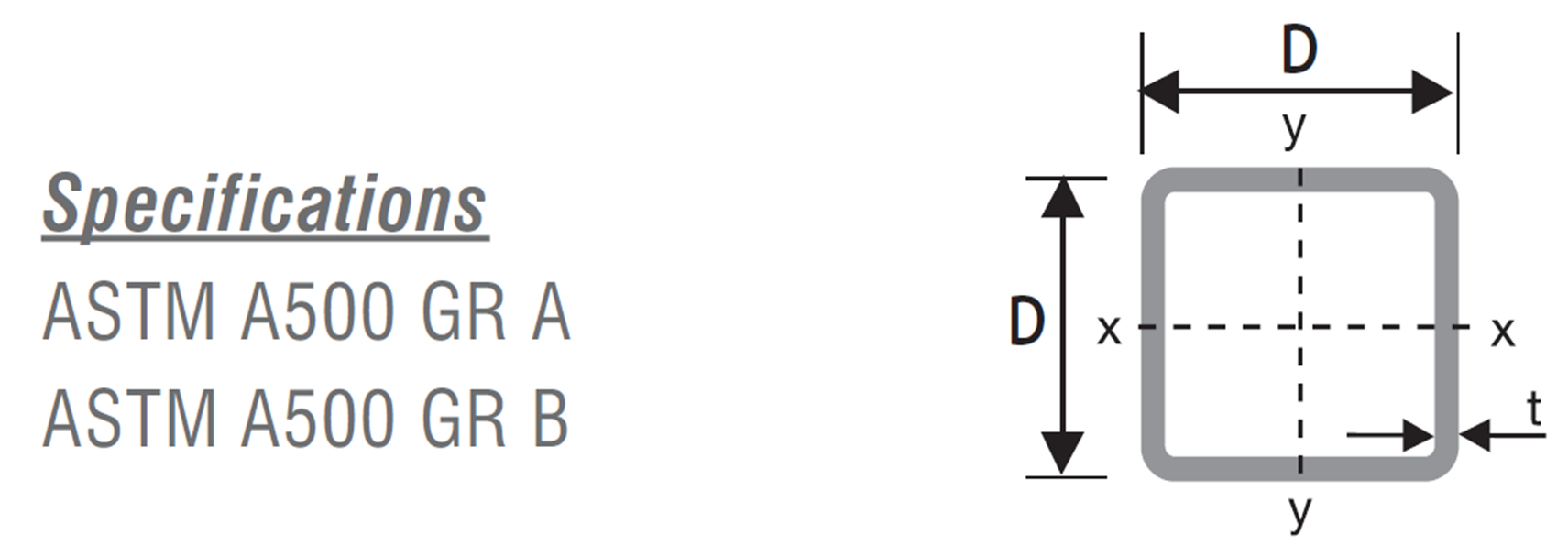

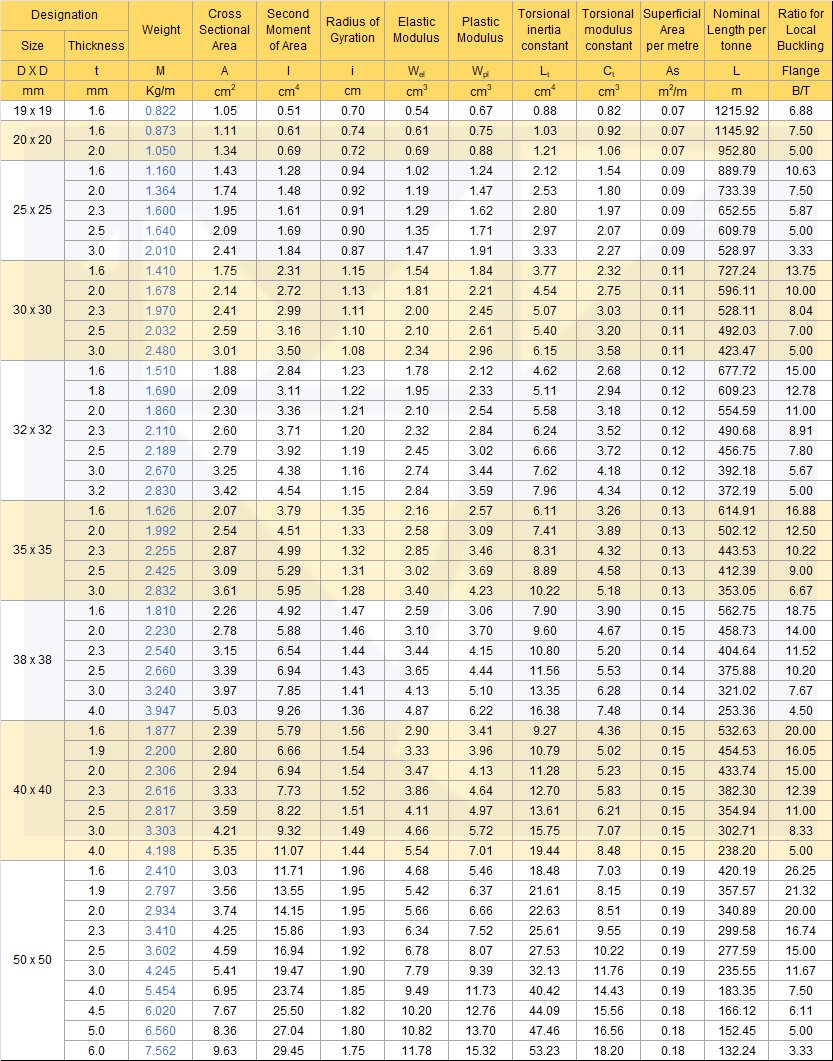

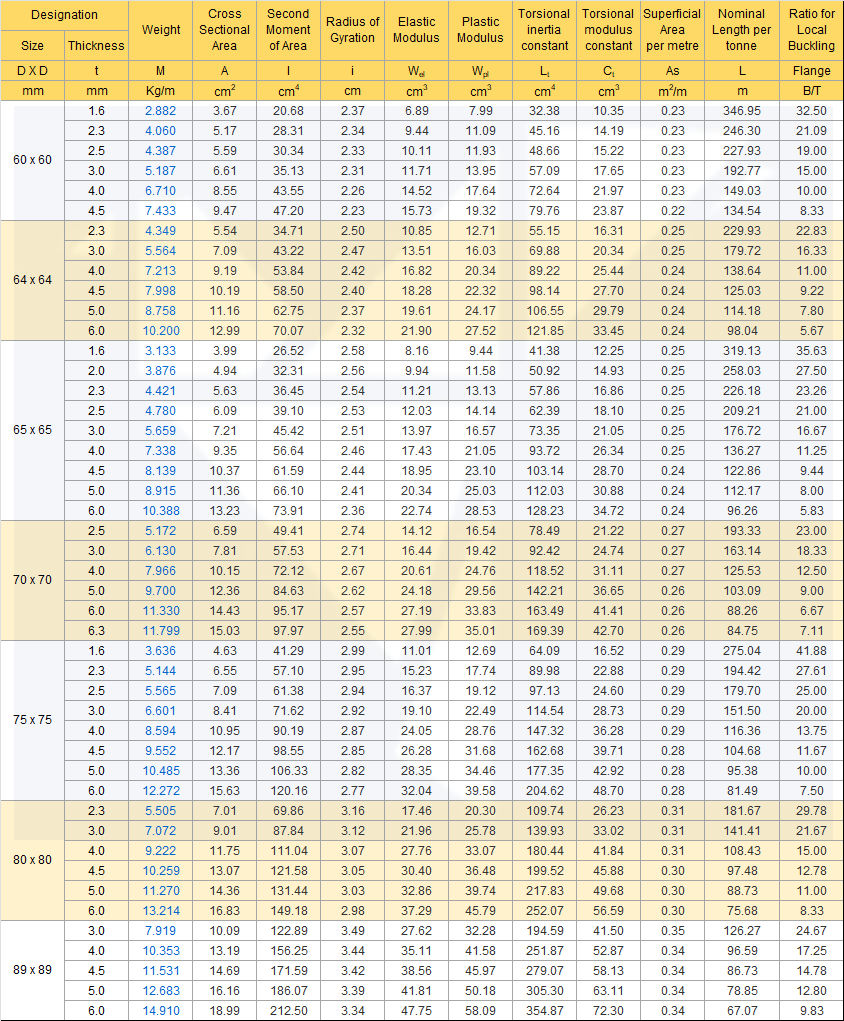

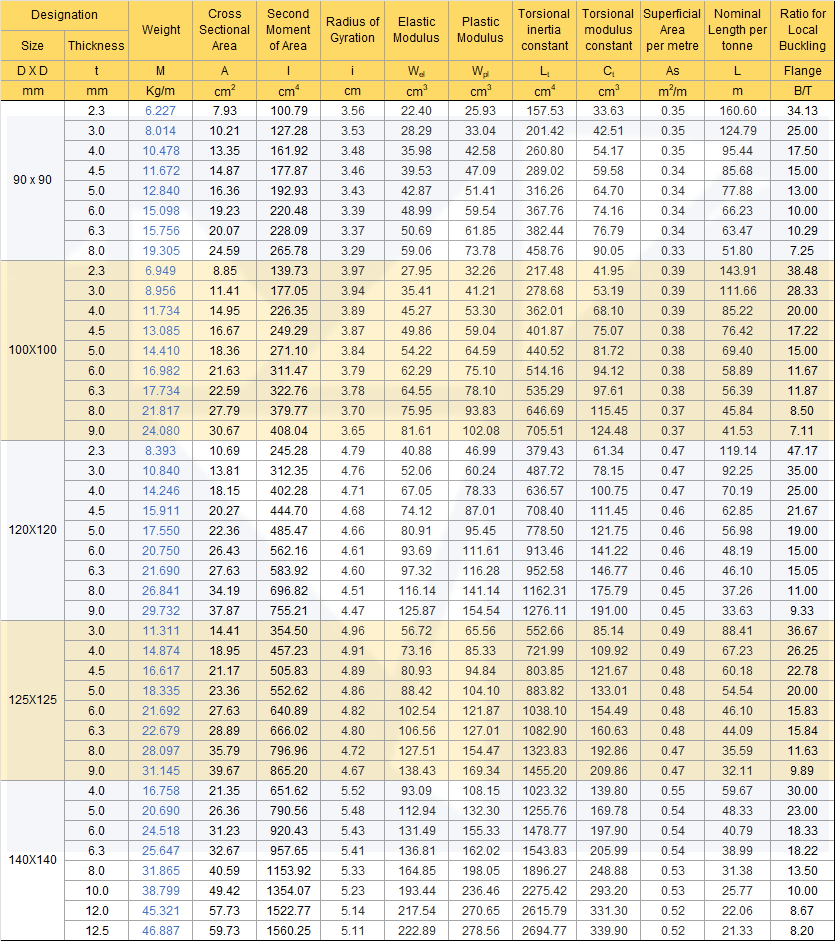

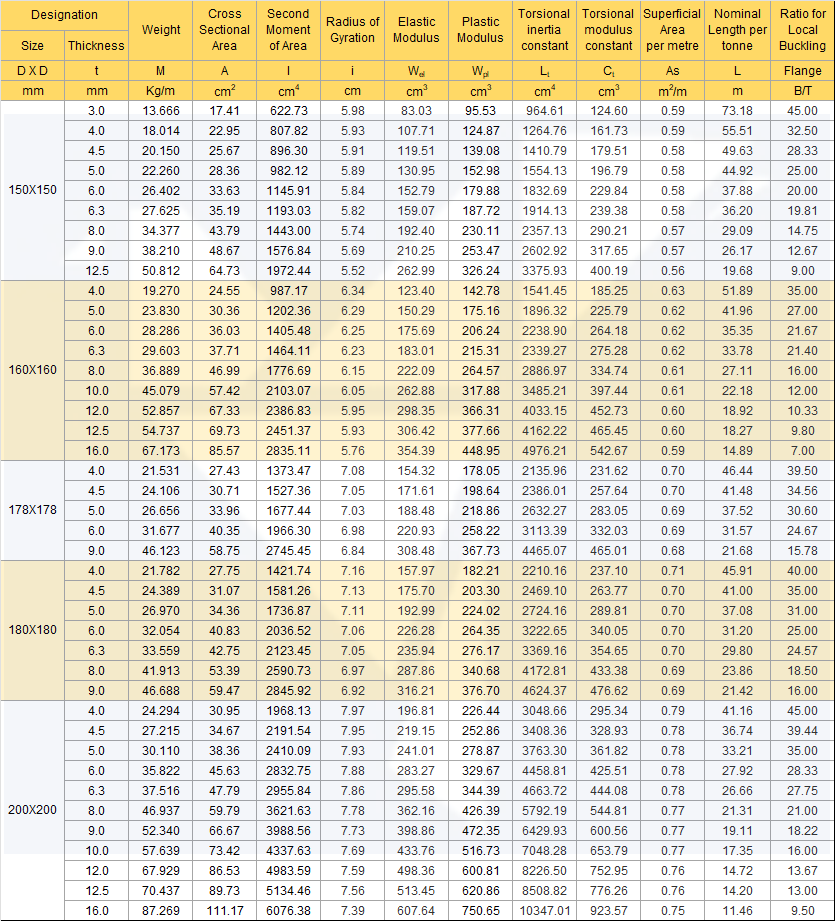

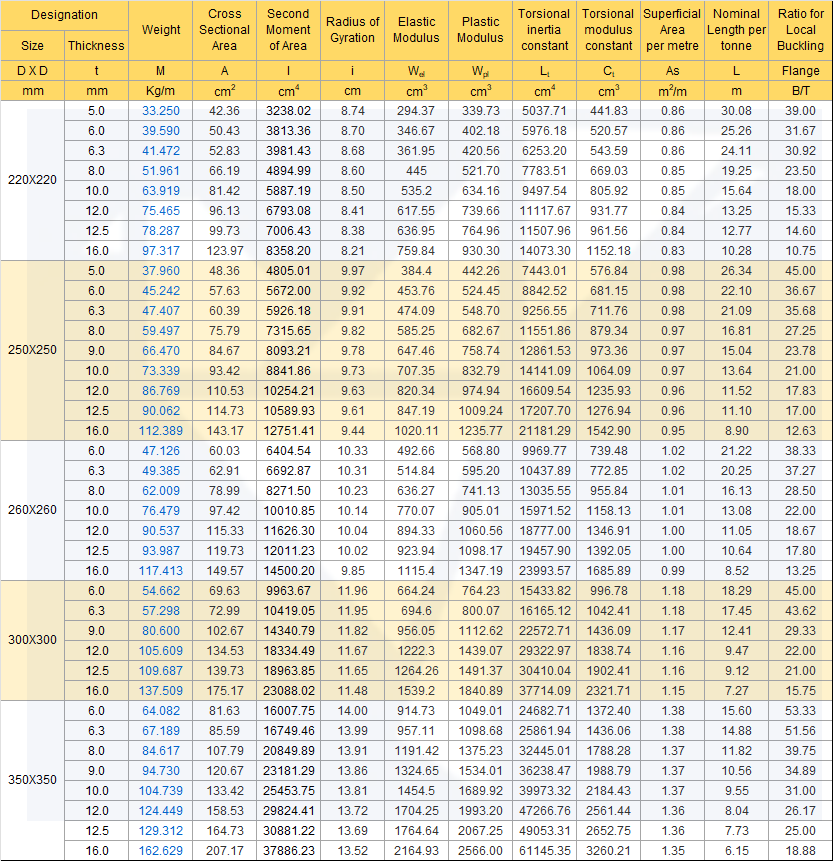

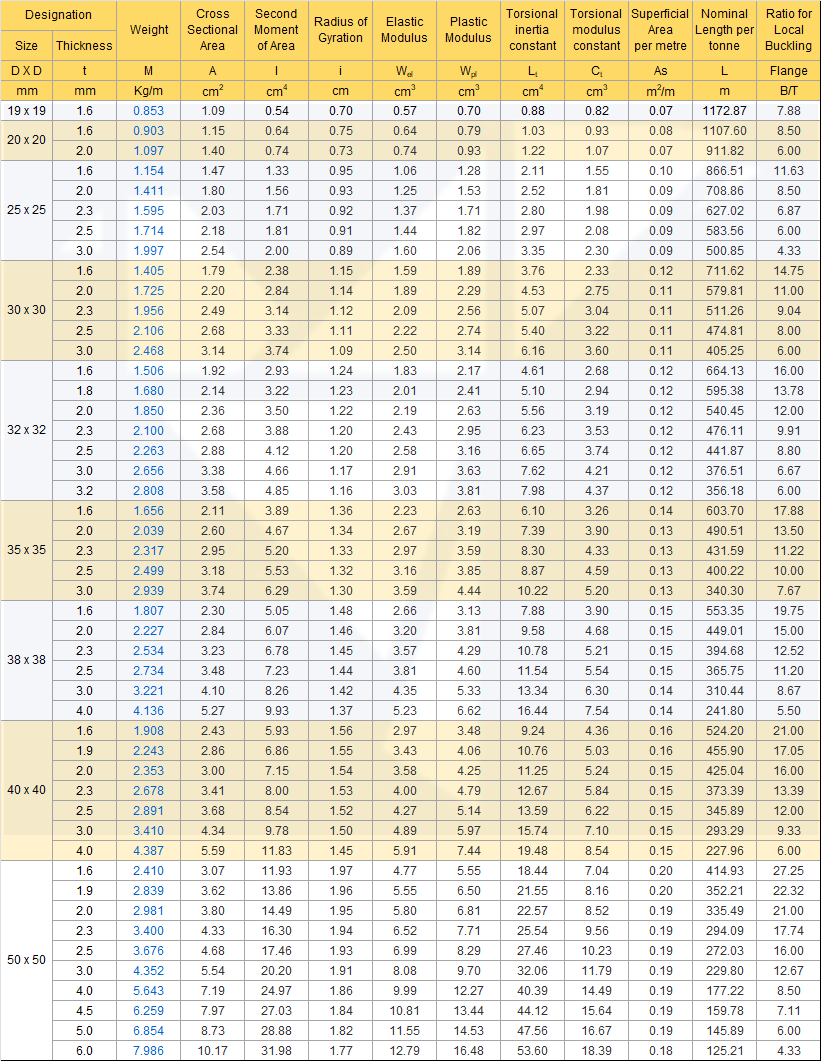

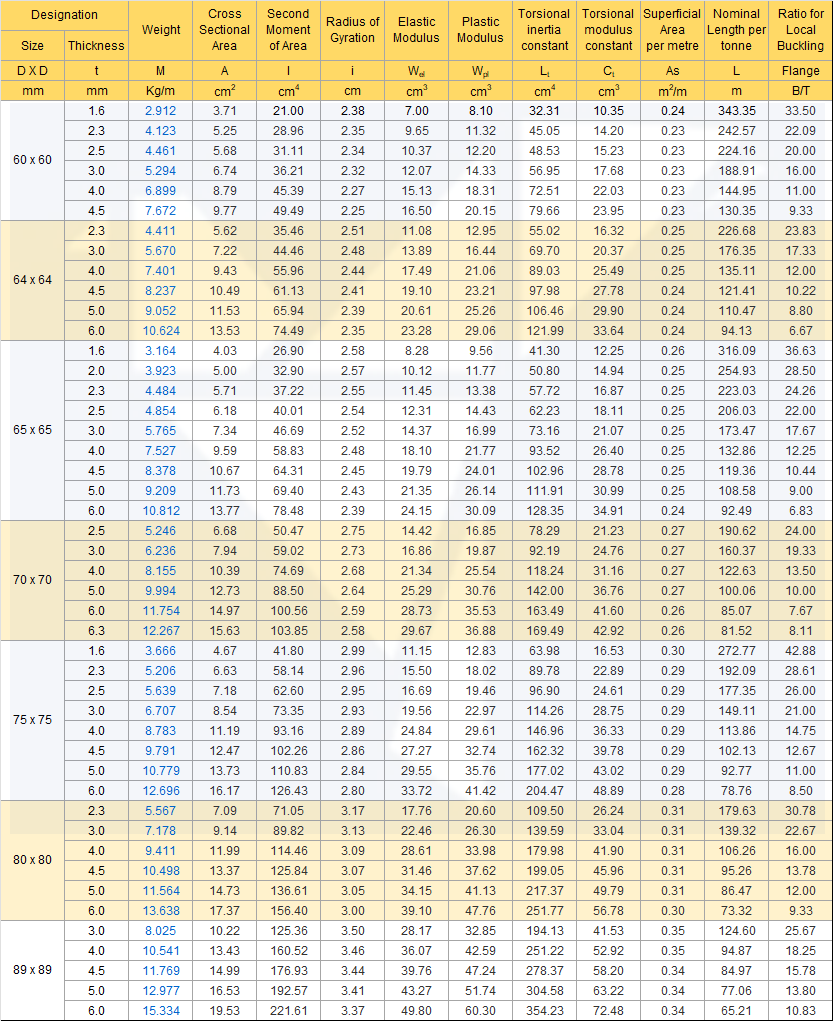

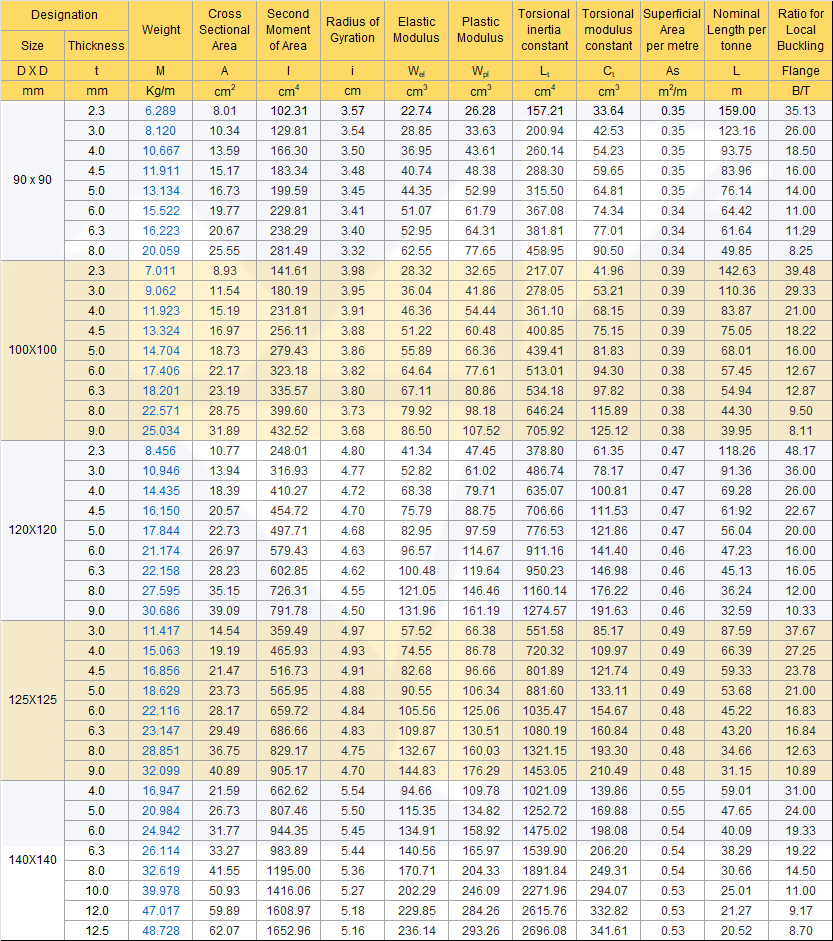

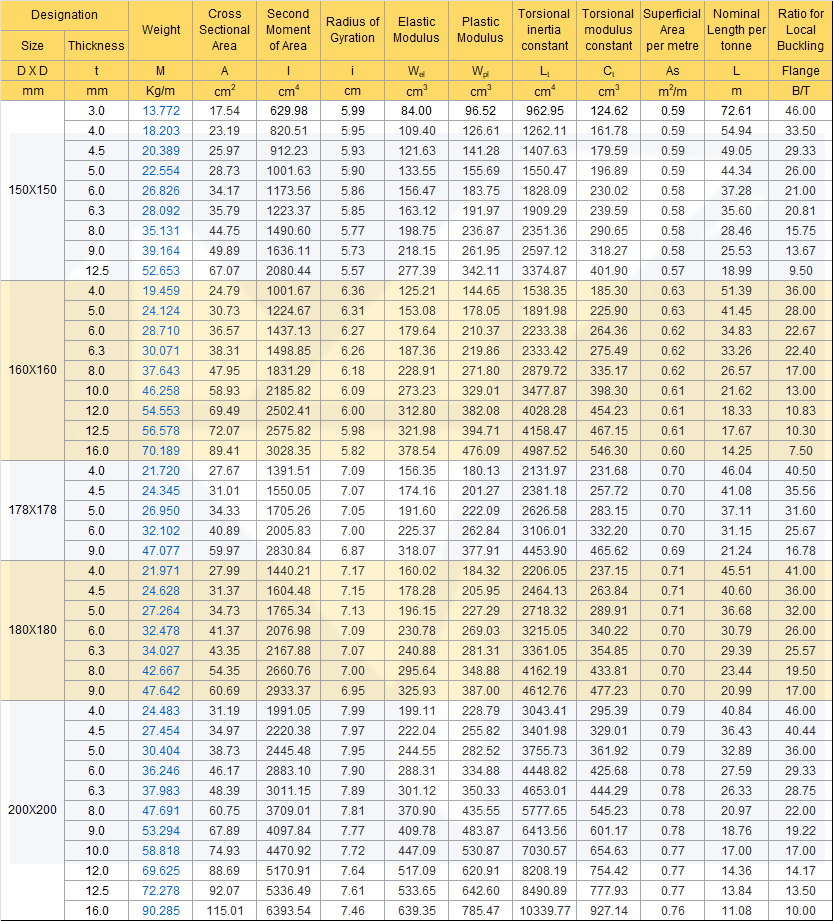

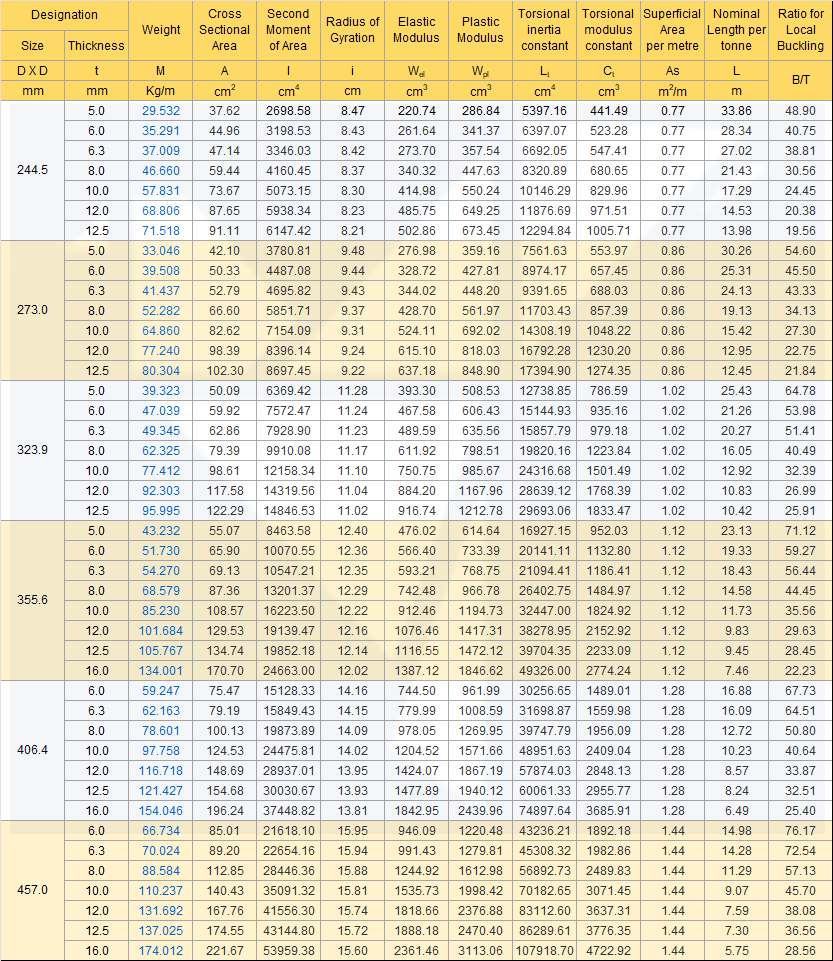

HOLLOW SECTIONS | ASTM A-500 - SQUARE

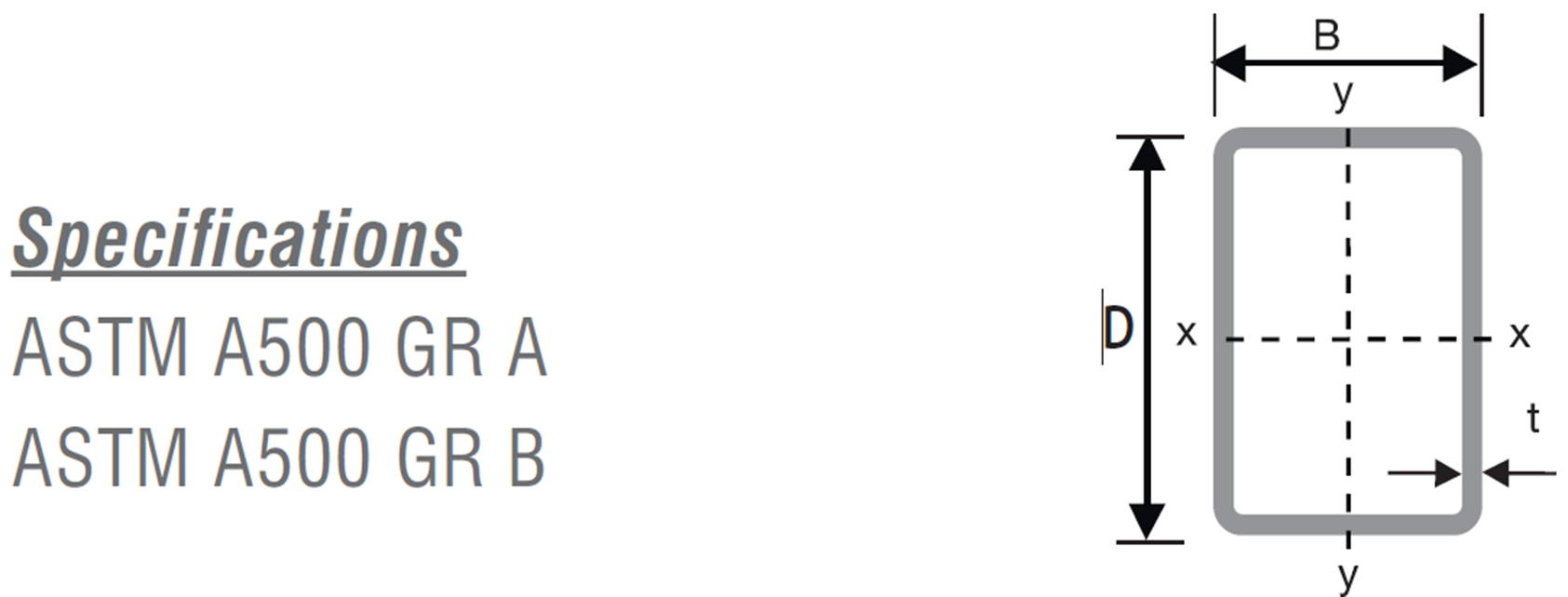

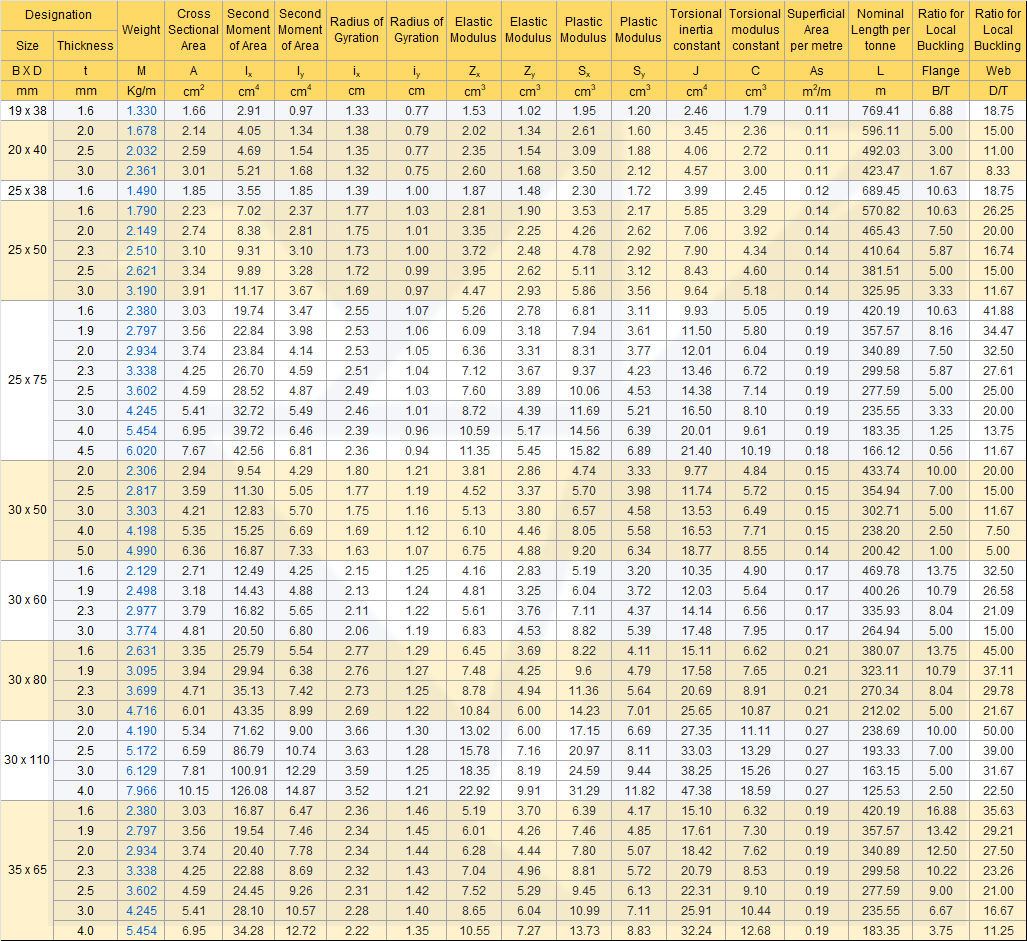

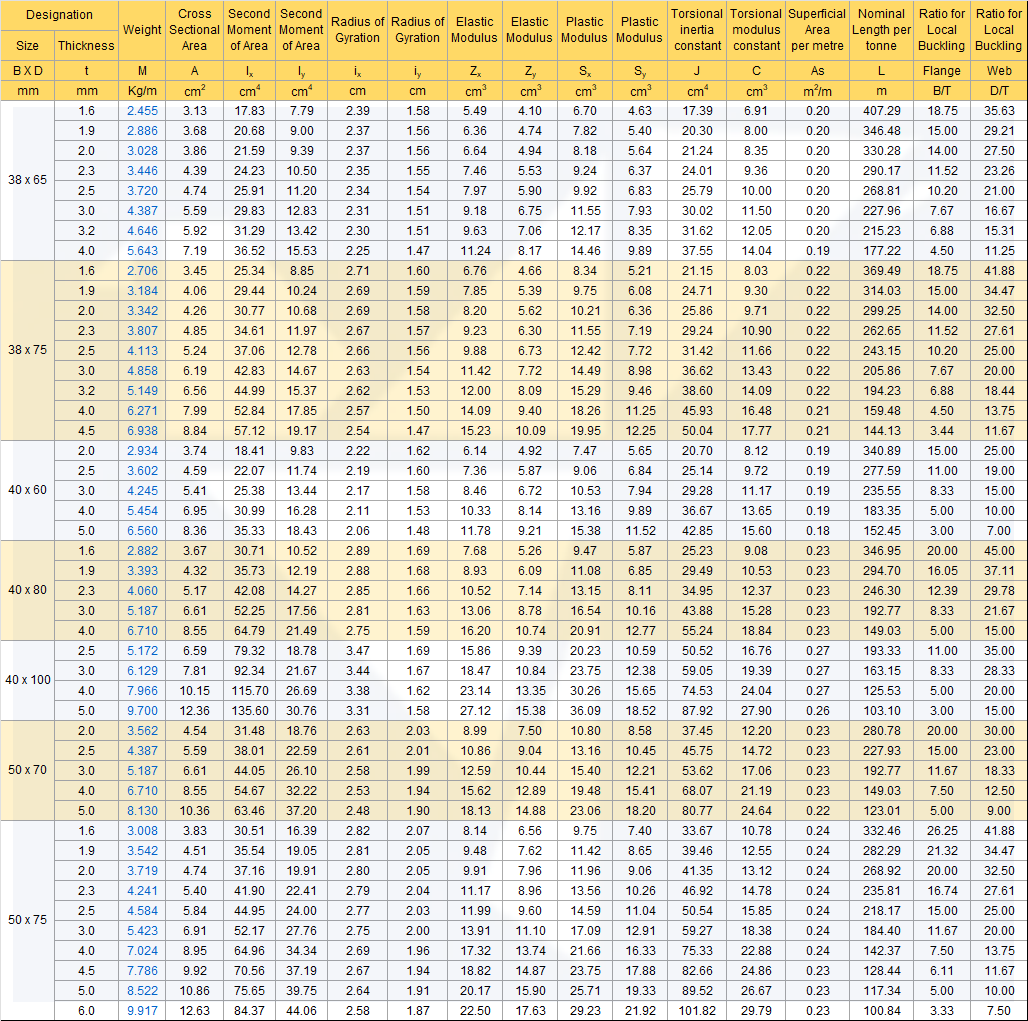

HOLLOW SECTIONS | ASTM A-500 - RECTANGULAR

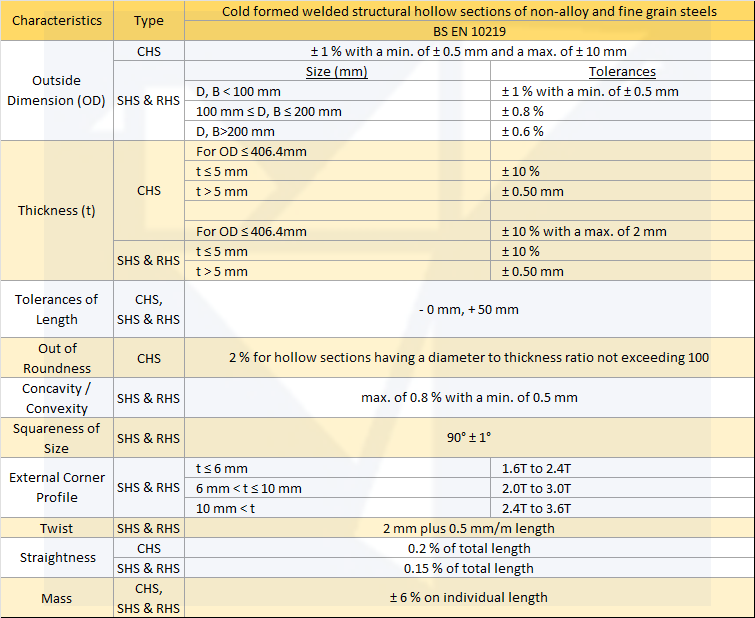

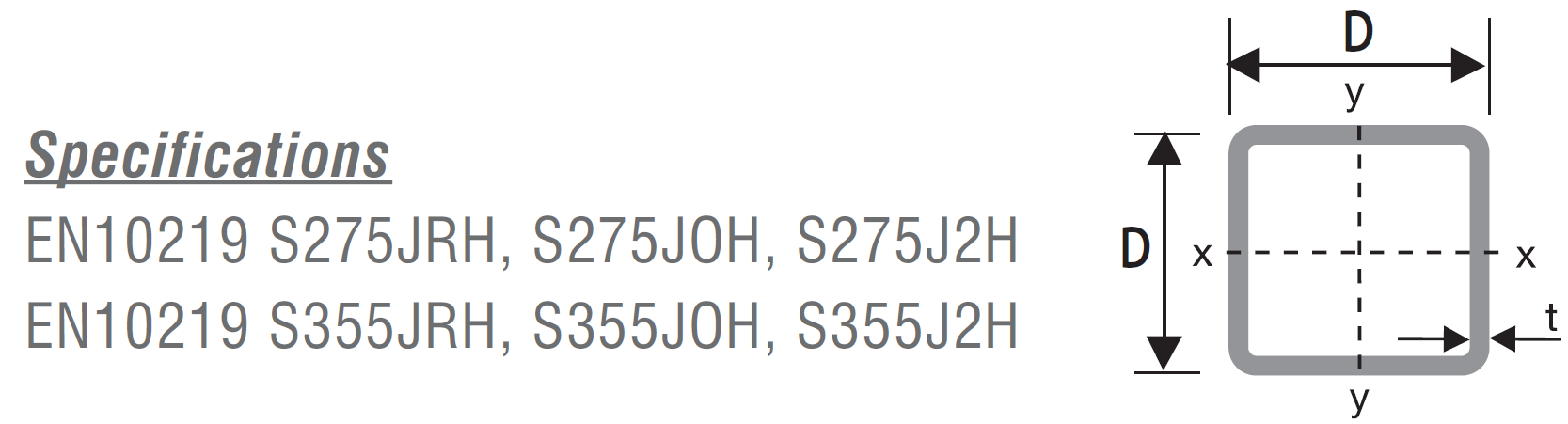

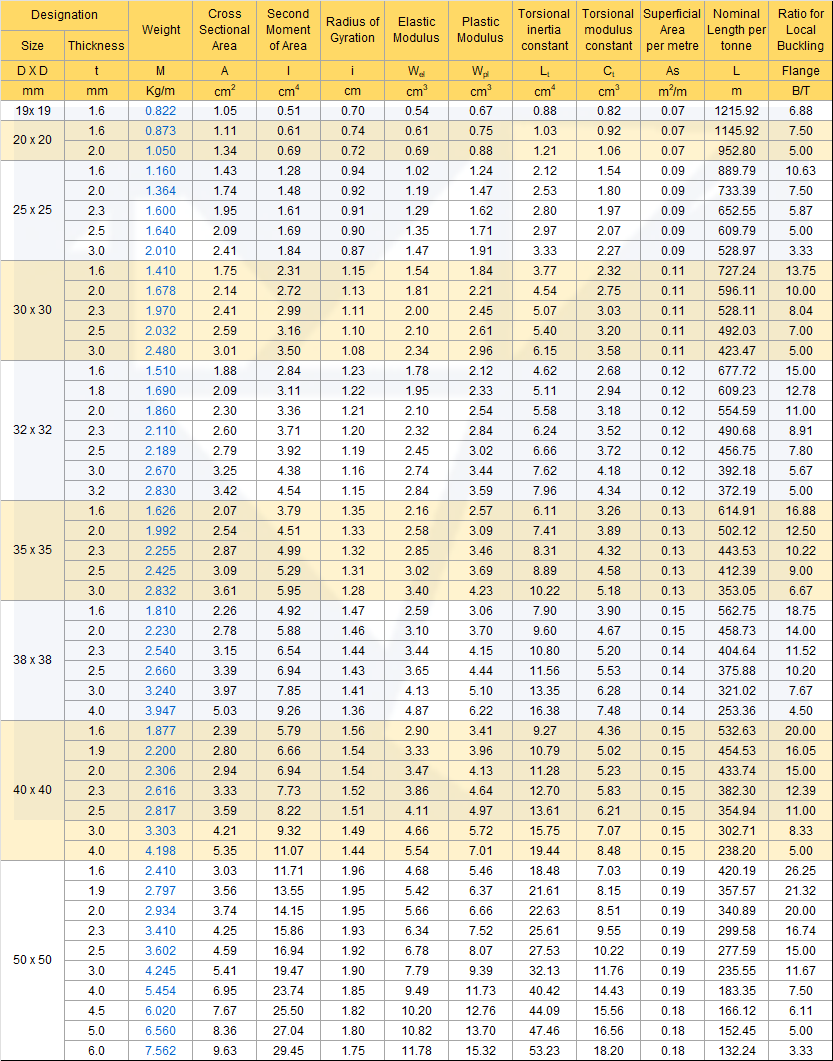

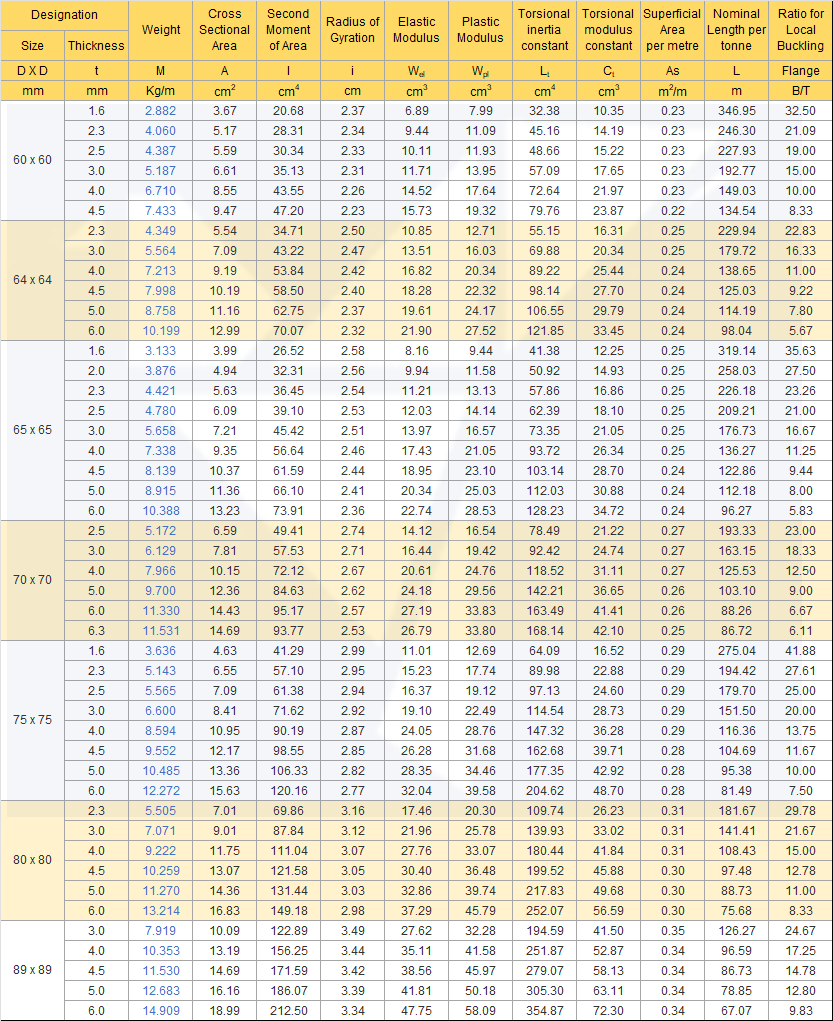

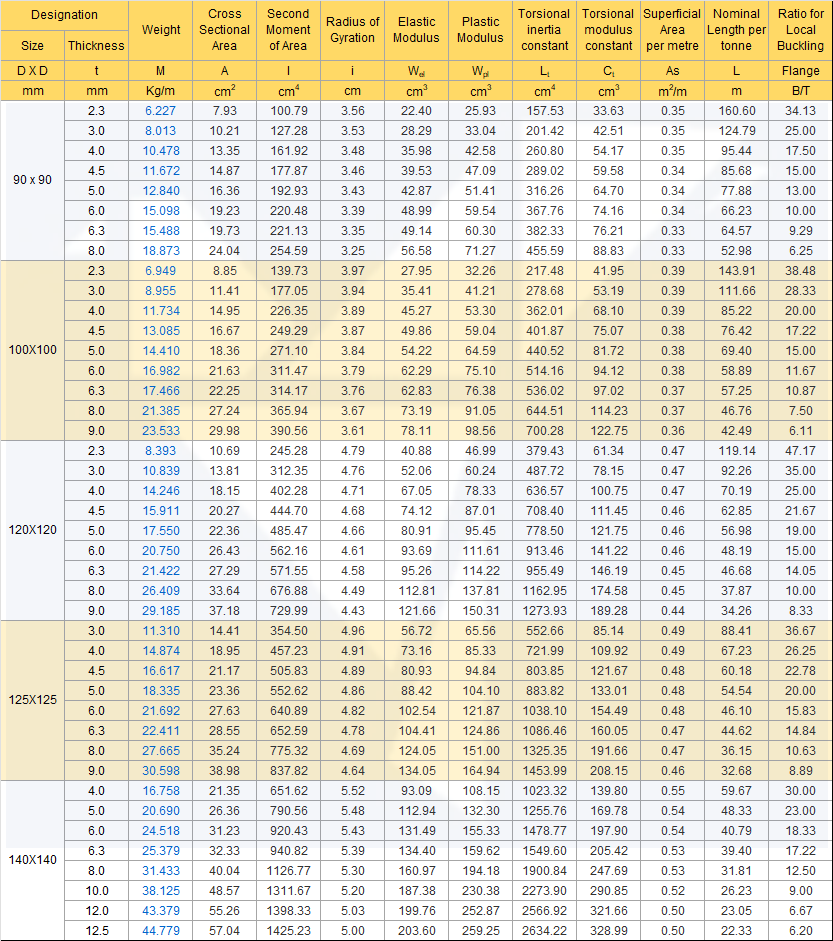

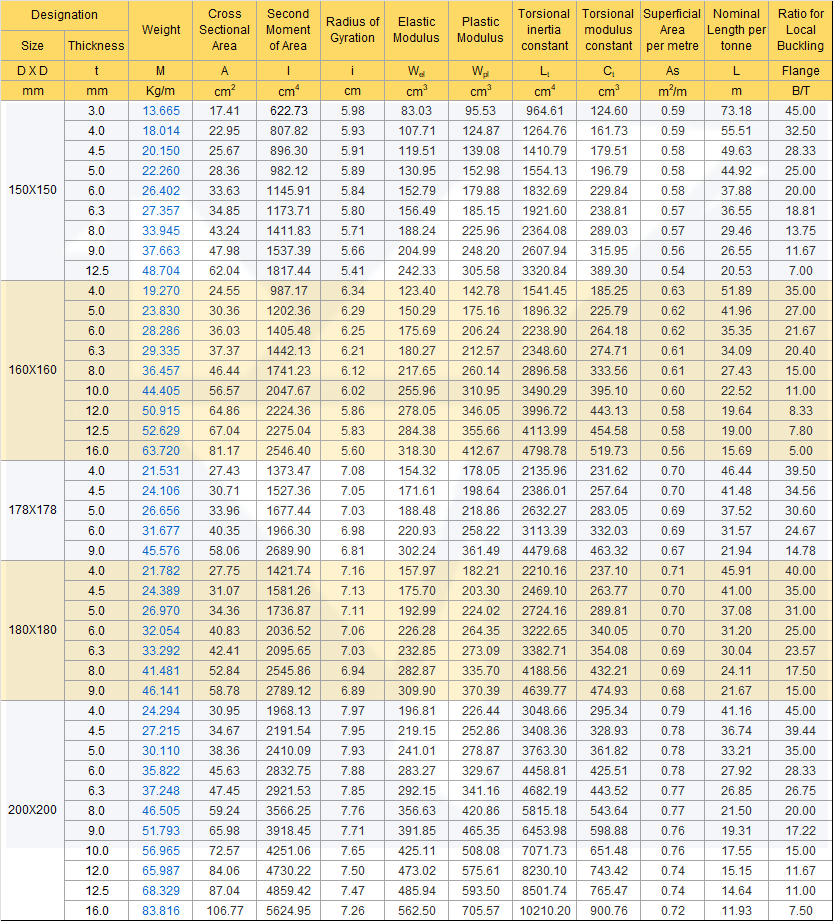

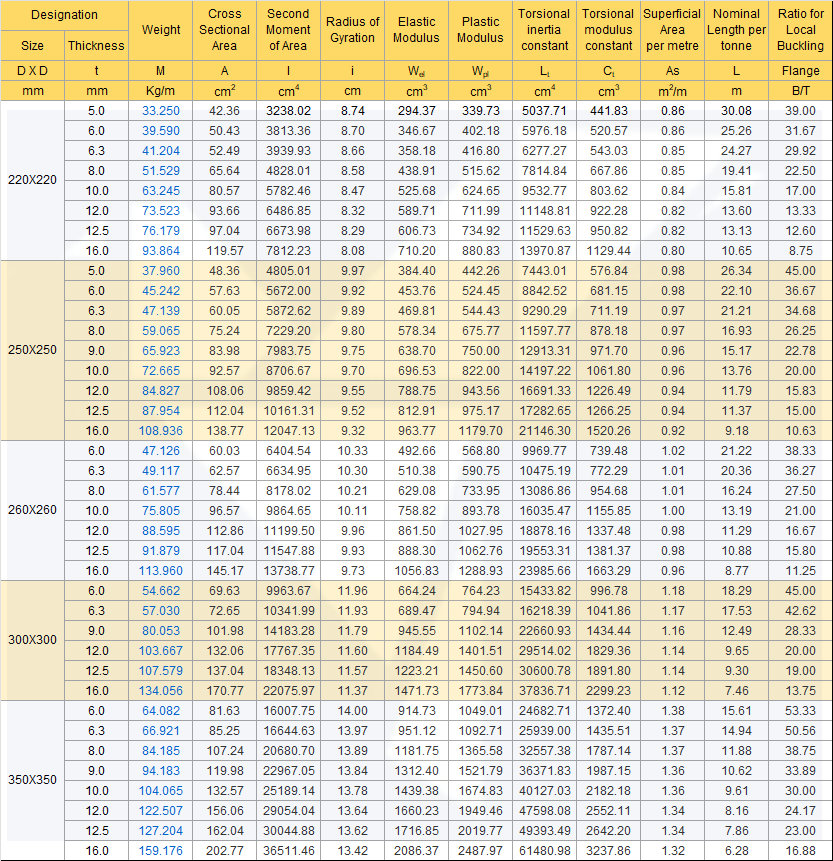

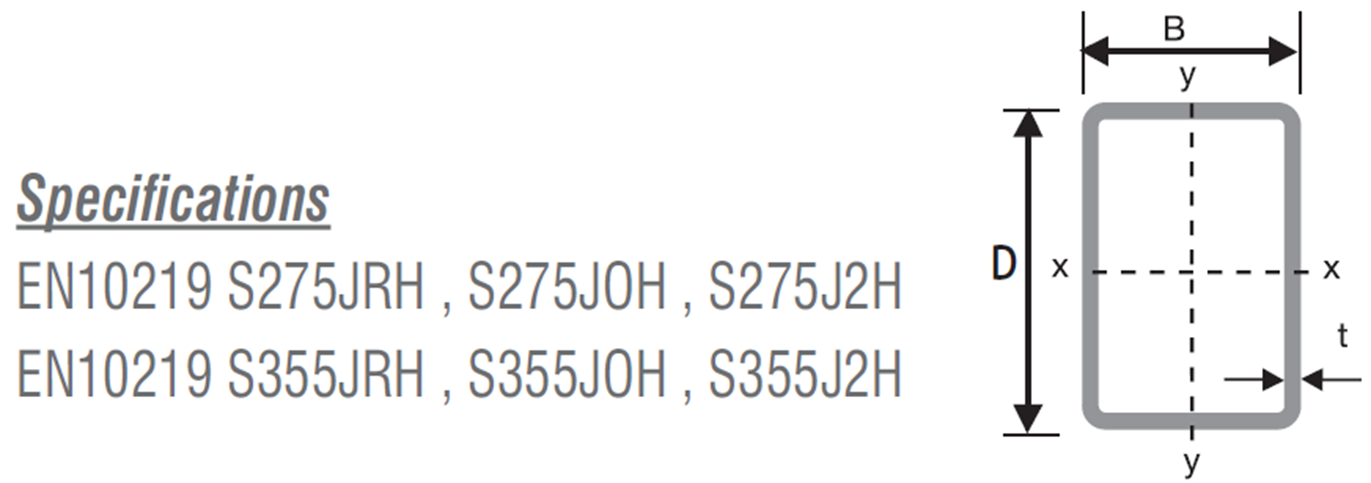

COLD FORMED HOLLOW SECTIONS | EN 10219 - SQUARE

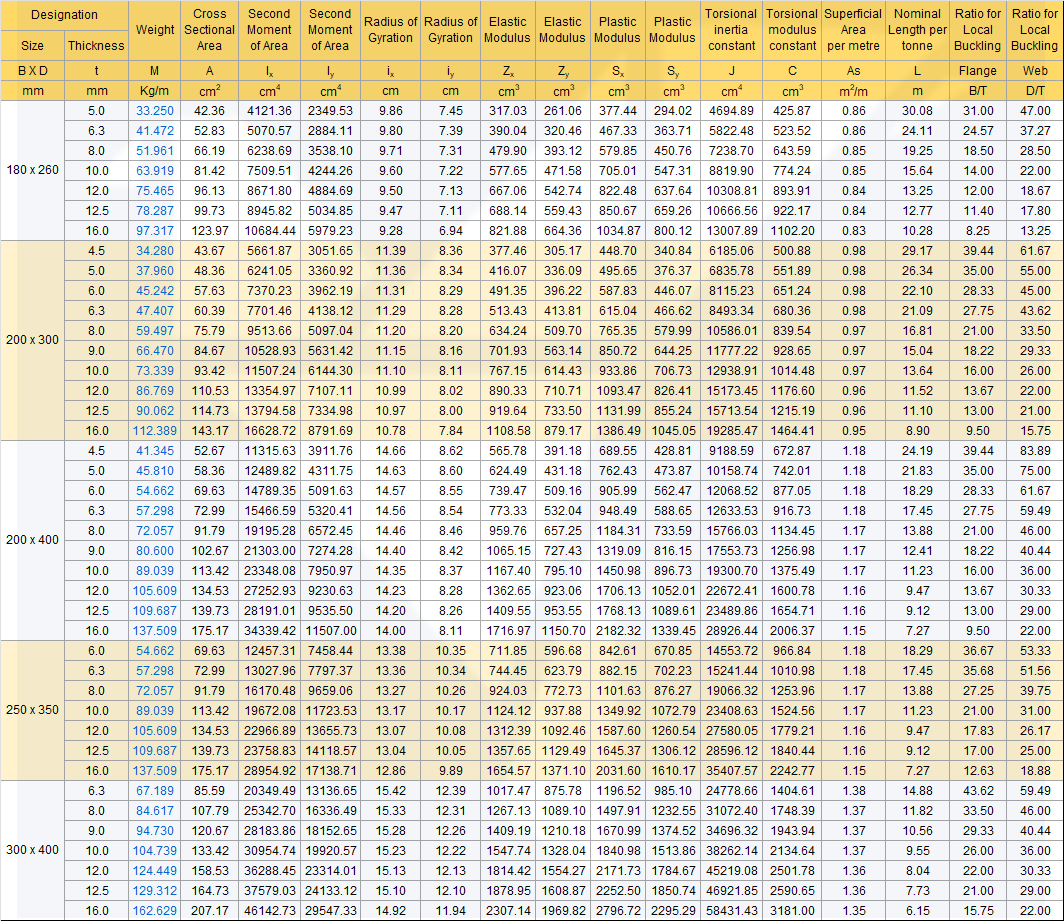

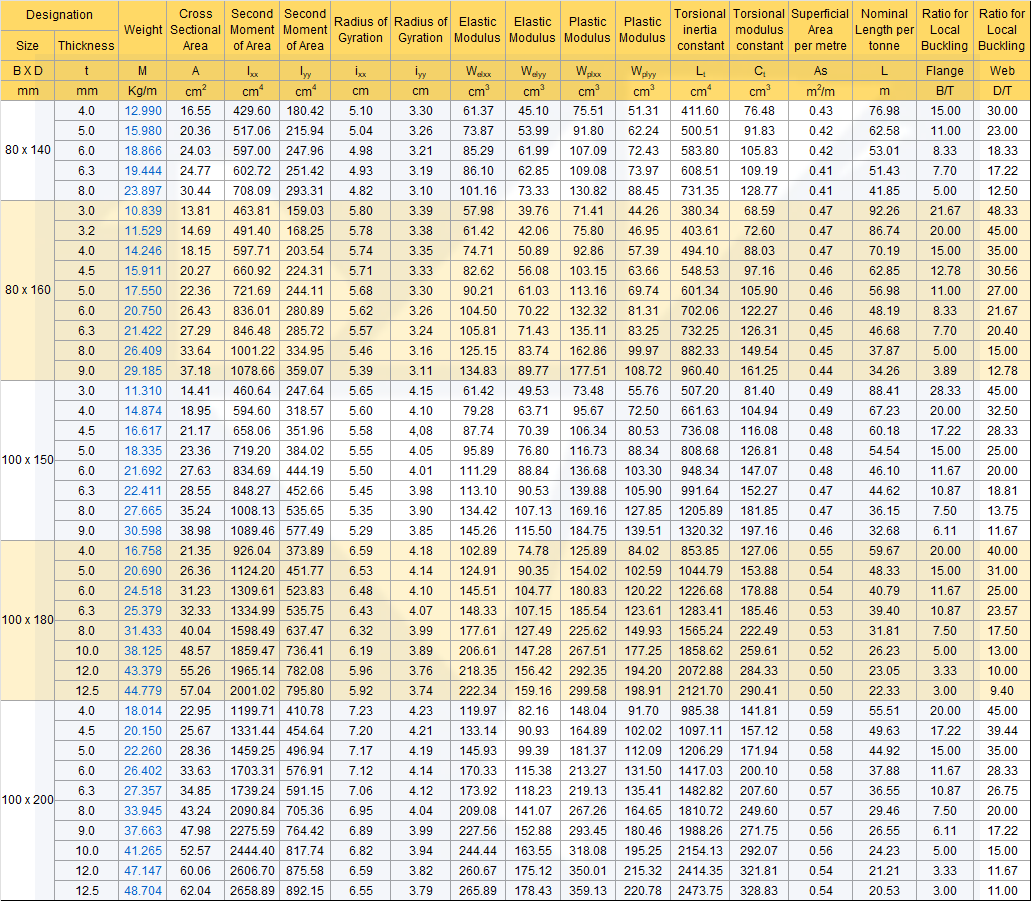

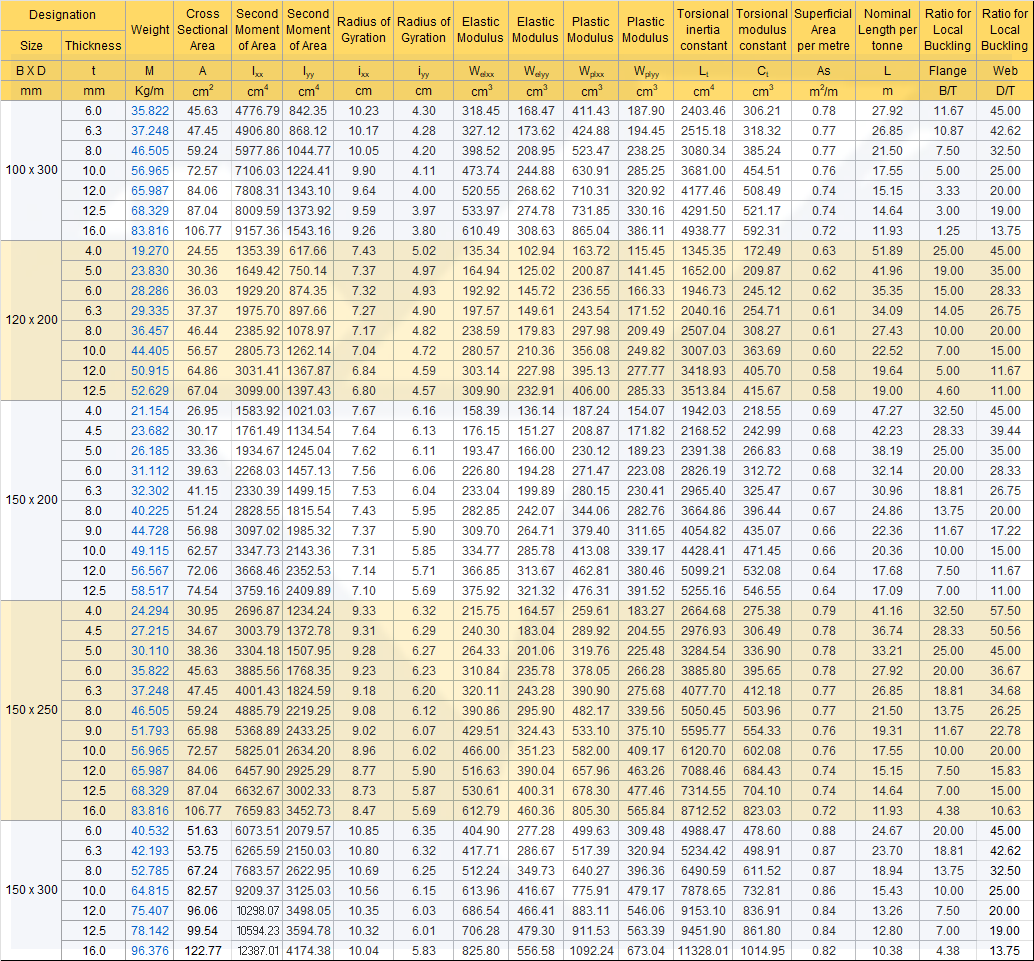

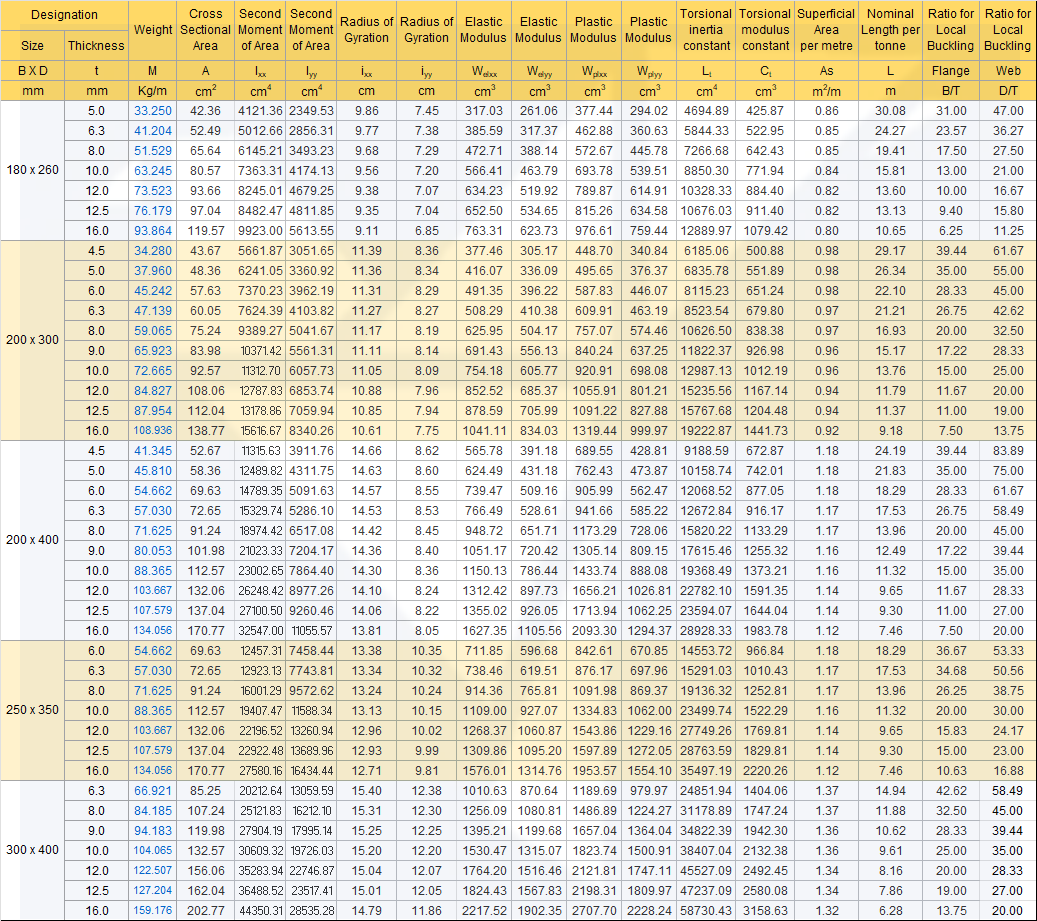

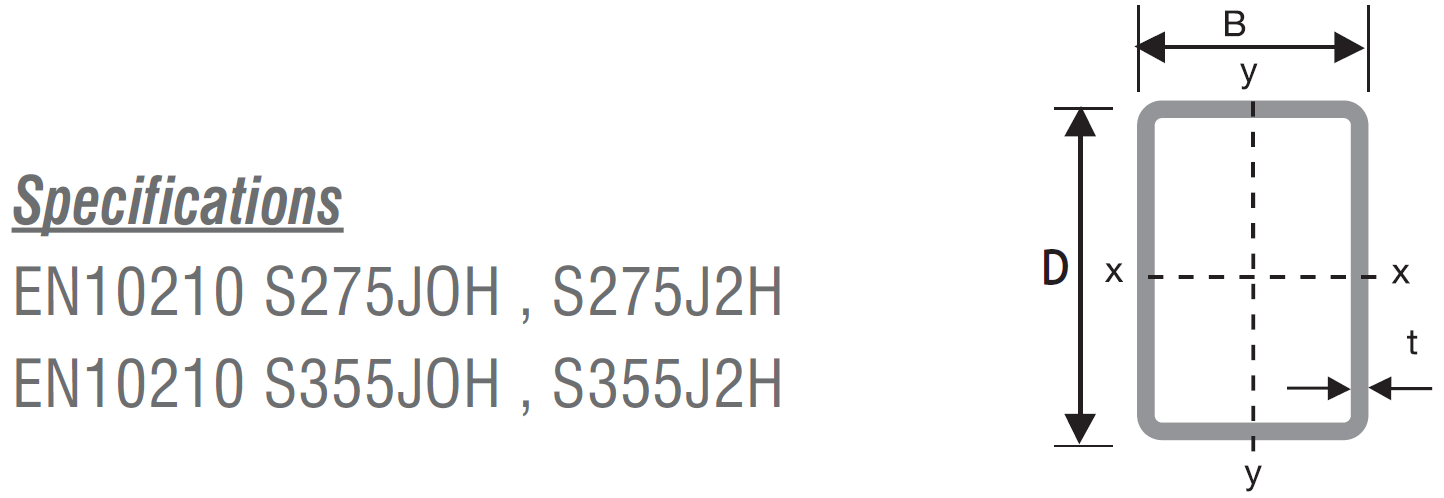

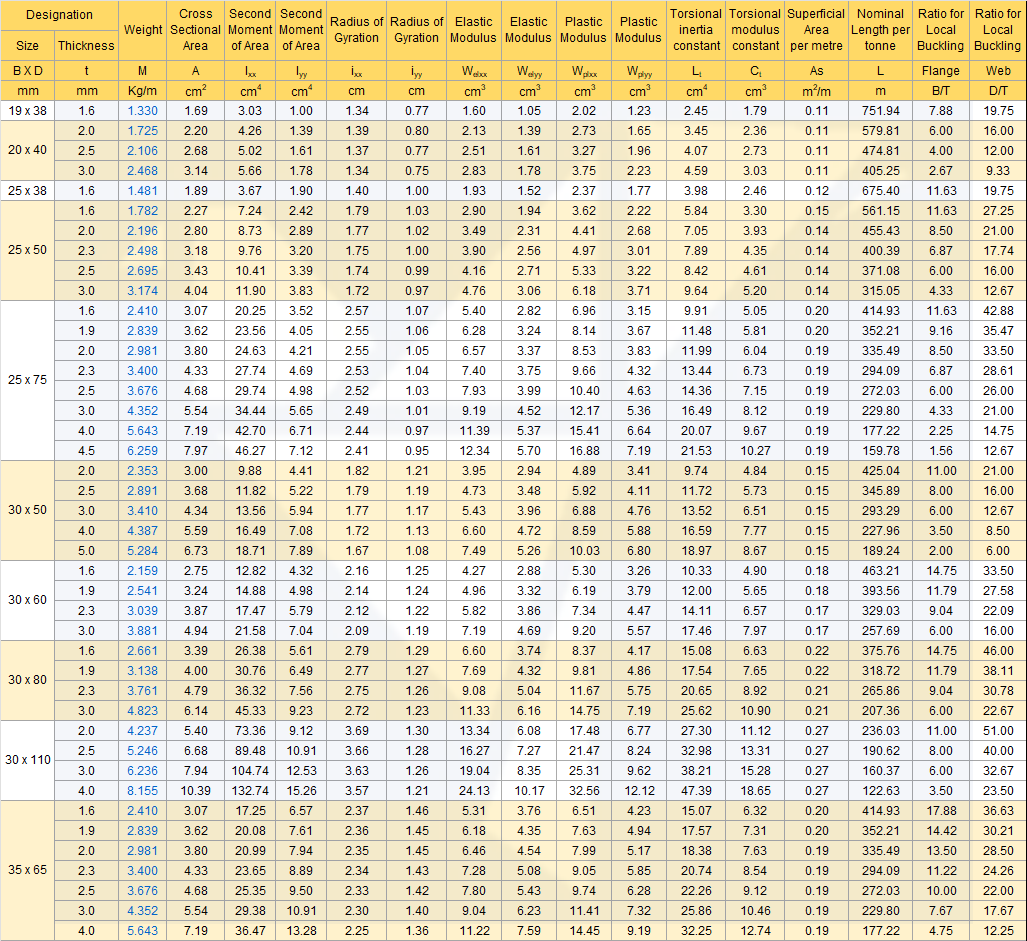

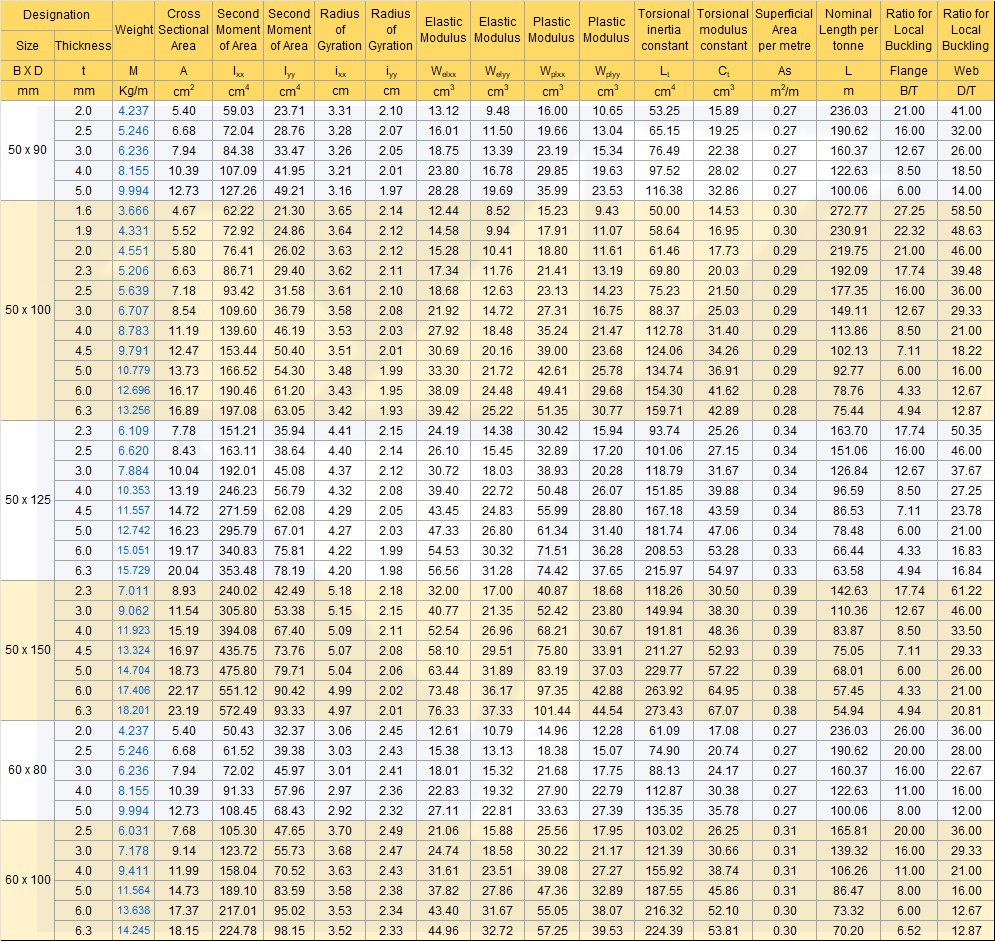

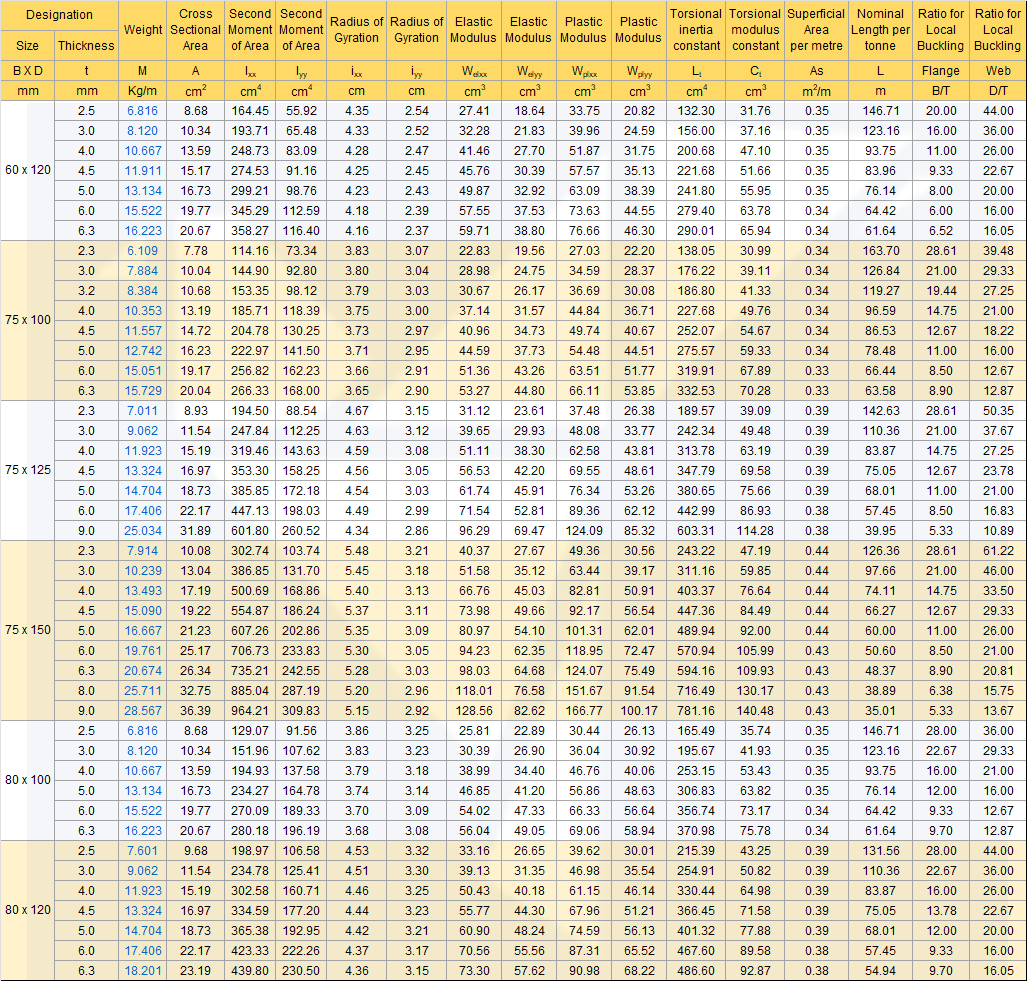

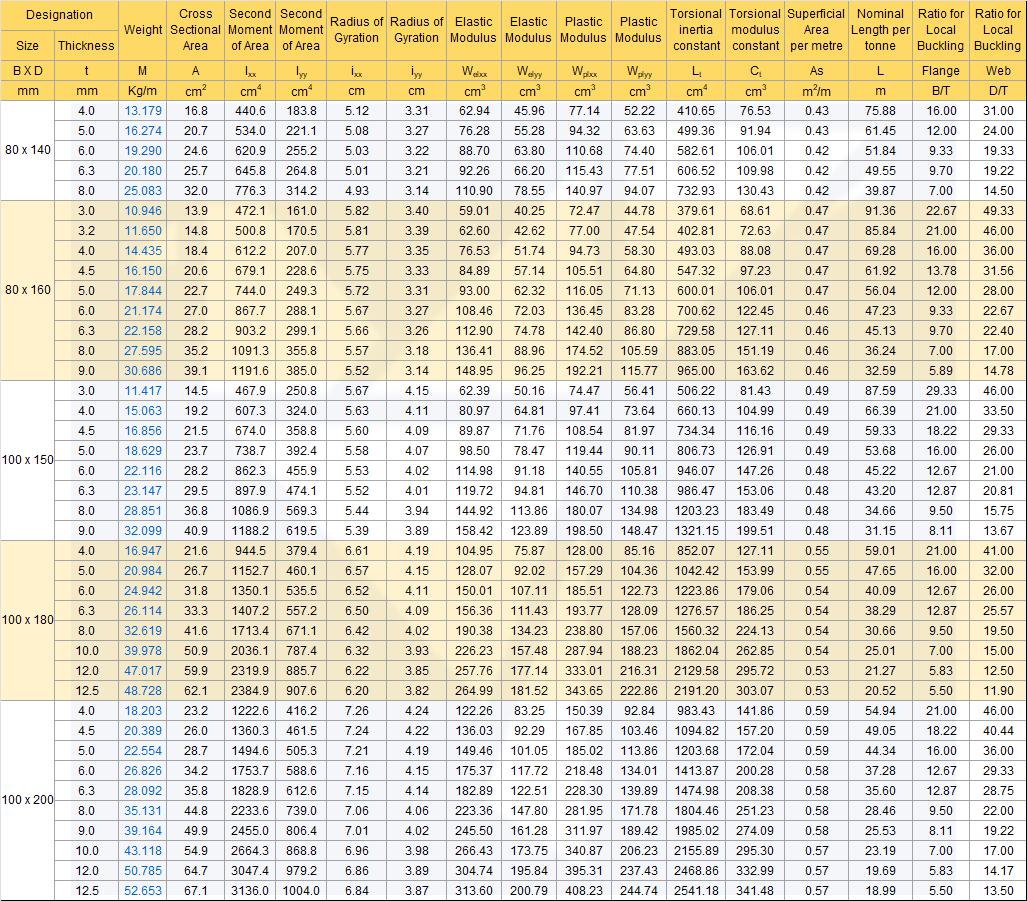

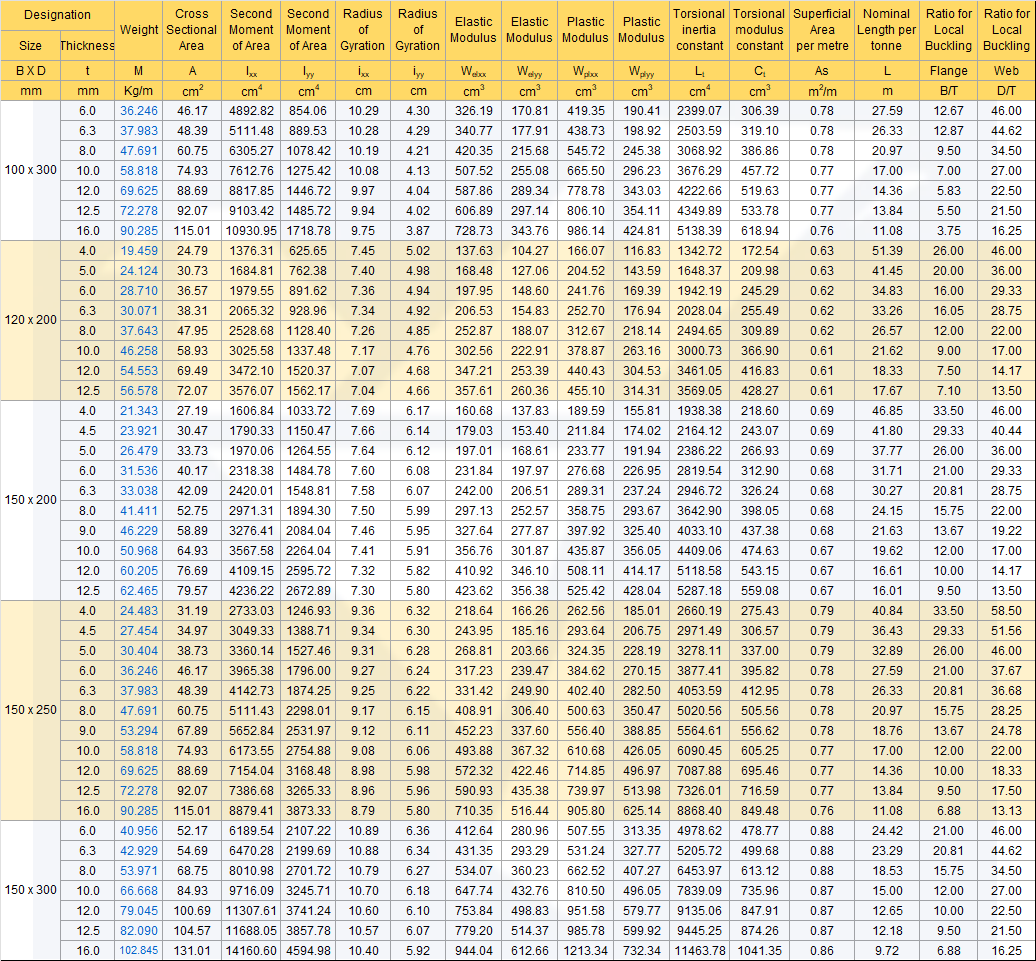

COLD FORMED HOLLOW SECTIONS | EN 10219 - RECTANGULAR

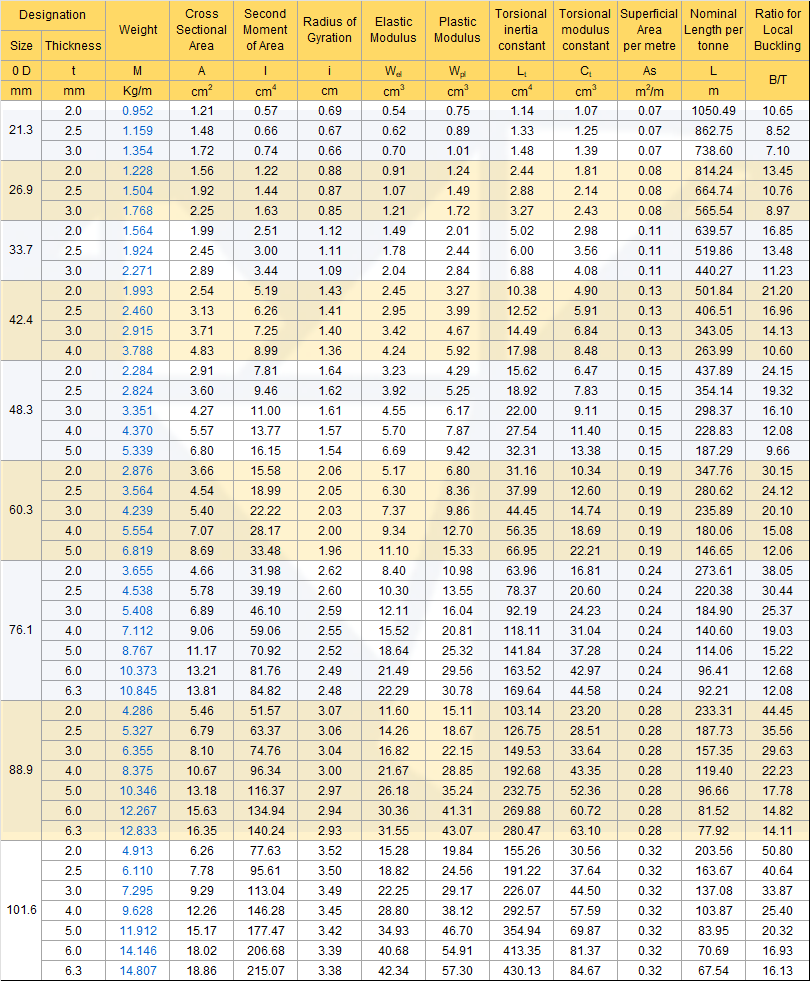

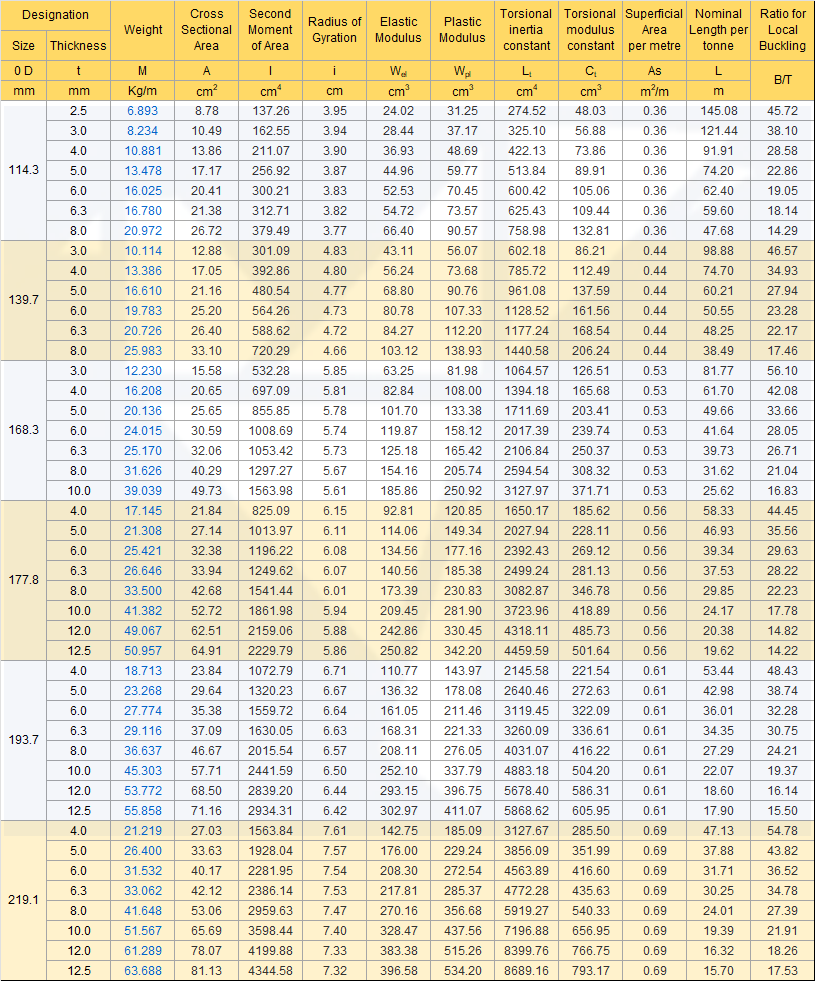

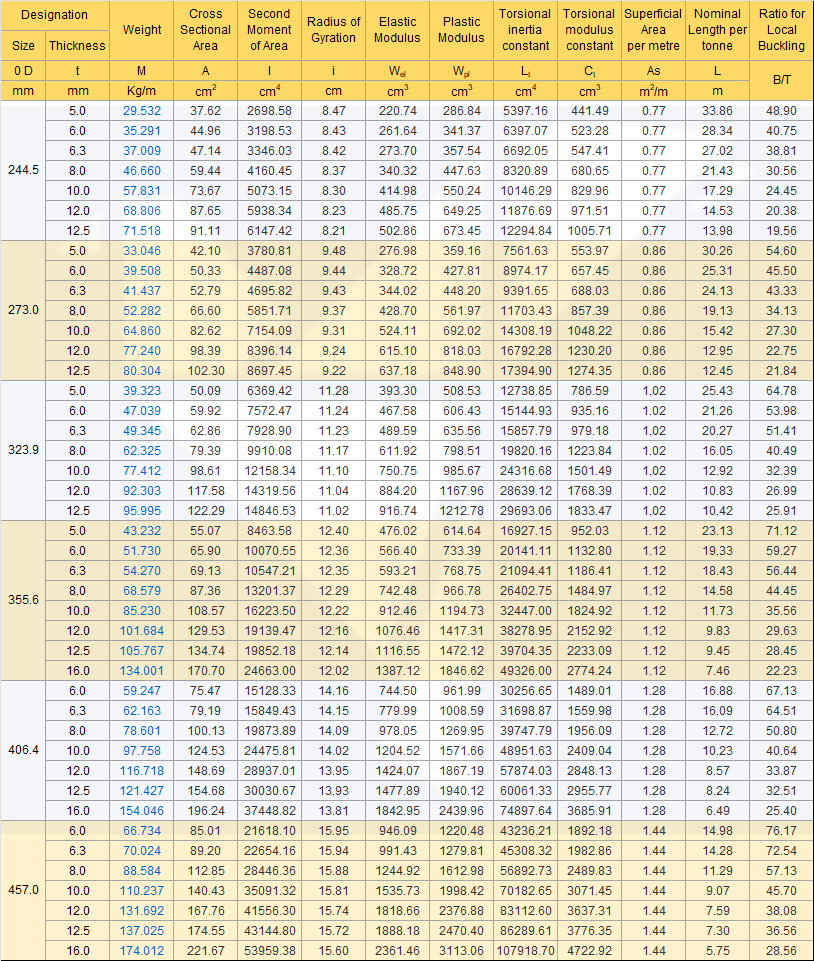

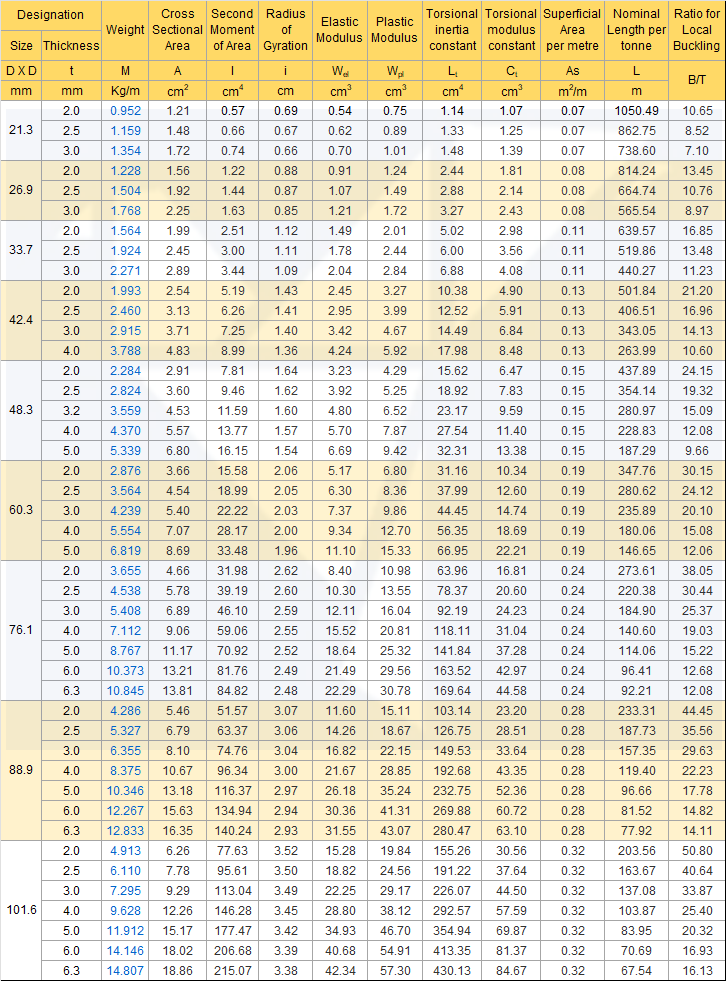

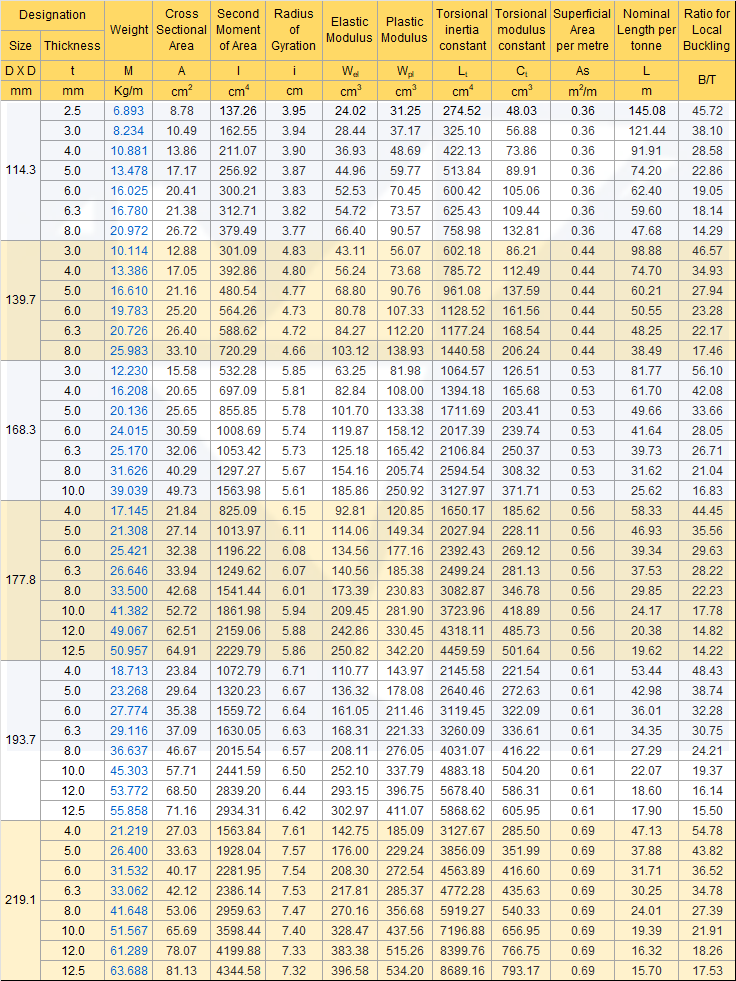

COLD FORMED HOLLOW SECTIONS | EN 10219 - CIRCULAR

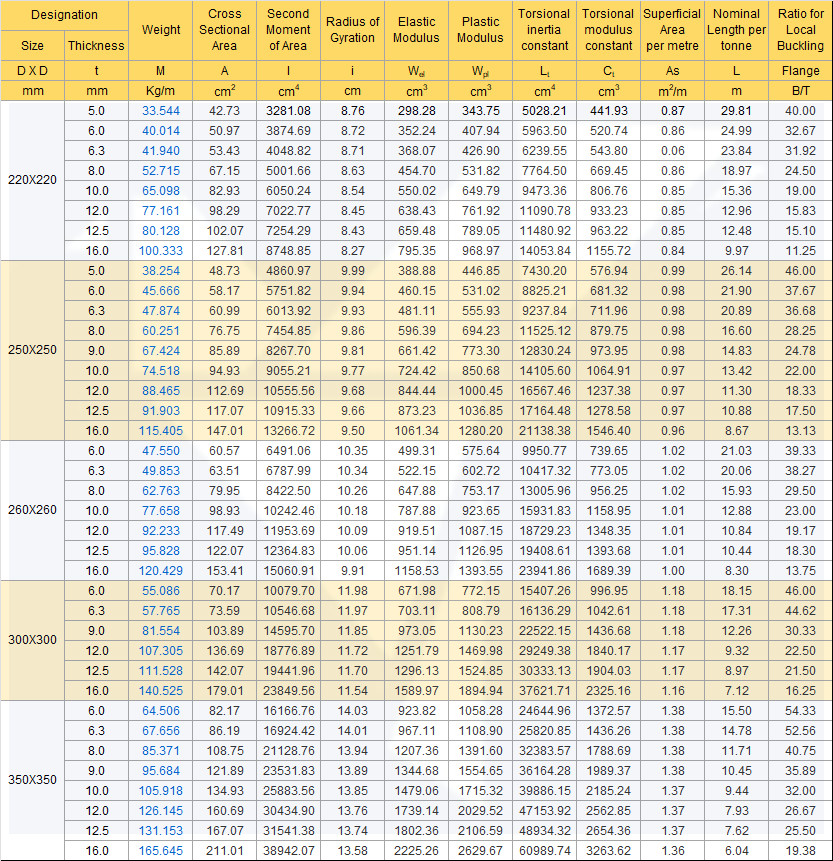

HOT FINISHED HOLLOW SECTIONS | EN 10210 - SQUARE

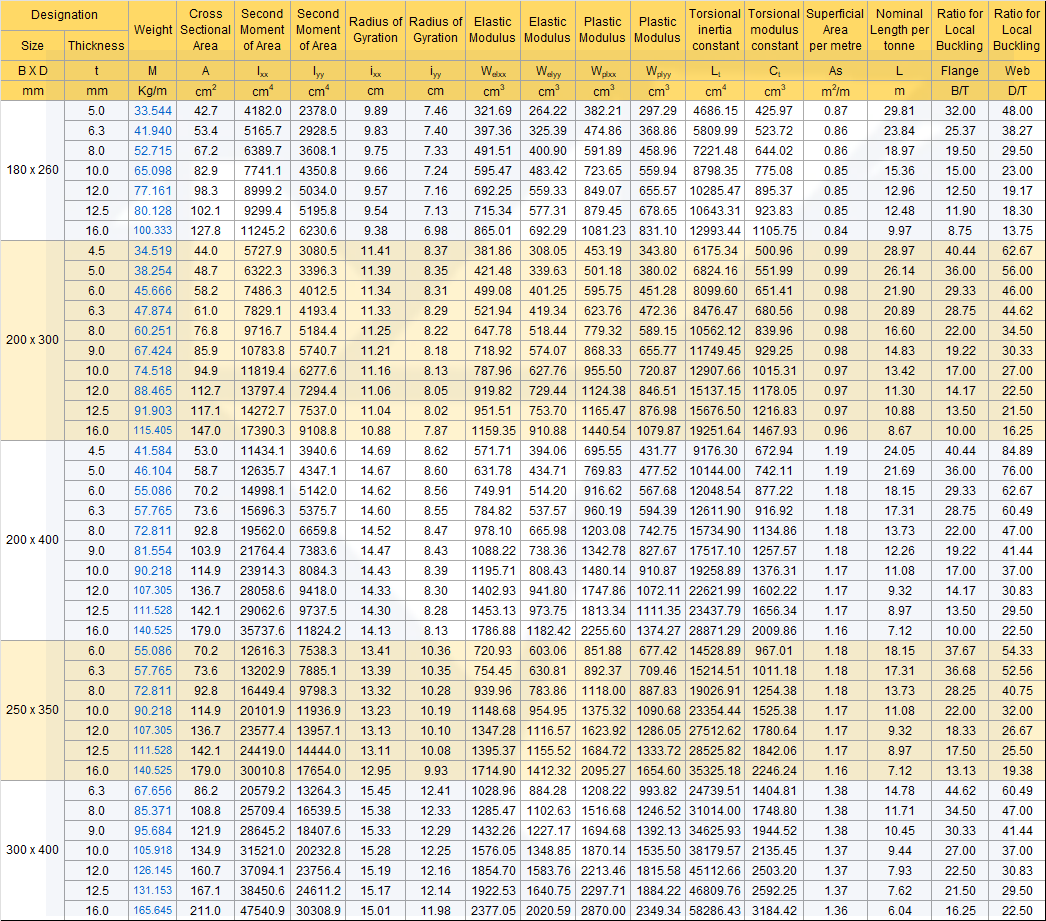

HOT FINISHED HOLLOW SECTIONS | EN 10210 - RECTANGULAR

HOT FINISHED HOLLOW SECTIONS | EN 10219 - CIRCULAR

FAQ

Steel hollow sections (SHS) are tubular steel sections that come in square, rectangular, or circular shapes. They are used in construction and engineering projects due to their high strength-to-weight ratio, versatility, and aesthetic appeal. These sections are commonly employed in structural applications, such as building frameworks, bridges, and support structures, as well as in mechanical and fabrication tasks. The hollow interior reduces weight without compromising strength, making SHS an efficient and cost-effective material choice.